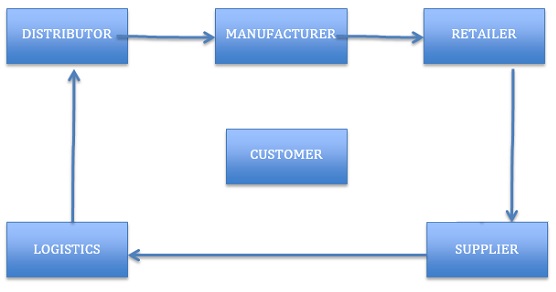

Supply chain management (SCM) systems are designed to streamline the flow of goods, information, and services from raw materials suppliers to end customers. These systems can provide a range of benefits to businesses, including improved efficiency, cost savings, and increased customer satisfaction. However, there are also potential drawbacks to implementing an SCM system, including initial cost and complexity.

One of the main advantages of SCM systems is their ability to improve efficiency. By automating and coordinating the flow of goods, information, and services throughout the supply chain, SCM systems can help businesses reduce the time and effort required to manage these processes. This can lead to faster turnaround times, shorter lead times, and reduced inventory levels, all of which can help businesses operate more efficiently and cost-effectively.

Another advantage of SCM systems is the potential for cost savings. By automating and optimizing supply chain processes, businesses can reduce the need for manual labor and minimize errors, leading to lower costs and improved profitability. SCM systems can also help businesses identify areas where they can negotiate better prices with suppliers or find more cost-effective transportation options, further reducing costs.

Improved customer satisfaction is another potential benefit of SCM systems. By providing real-time visibility into inventory levels and delivery schedules, businesses can more accurately predict and meet customer demand, leading to higher customer satisfaction. SCM systems can also help businesses respond more quickly to customer inquiries and concerns, further improving the customer experience.

Despite these advantages, there are also potential drawbacks to implementing an SCM system. One of the main challenges is the initial cost of implementation. SCM systems can be complex and require significant investment in hardware, software, and training. Additionally, there may be ongoing maintenance and upgrade costs associated with maintaining an SCM system.

Another potential disadvantage is the complexity of SCM systems. These systems often involve integrating multiple software applications and processes, which can be challenging to implement and manage. There may also be a learning curve for employees as they adapt to new processes and technologies.

In conclusion, SCM systems can provide a range of benefits to businesses, including improved efficiency, cost savings, and increased customer satisfaction. However, there are also potential drawbacks to consider, including the initial cost and complexity of implementation. Whether or not an SCM system is a good fit for a particular business will depend on its specific needs and resources.

Pros and Cons of Supply Chain Management

Hence, for example, suppose the production department is producing goods in time but due to the lackluster attitude of dispatch departments goods are not reaching on time to ultimate customers than supply chain management can easily identify the problem area which is the dispatch department and hence can take action against the concerned people. Whilst engaging in supply chains offers benefits, sourcing globally involves the management of different cultures, religions, and time zones, as well as good ethical practices and foreign currencies. We hope that you have liked this entire discussion on supply chain management. Convert these raw materials into finished products. In order to understand more about this concept, one should look at the advantages and disadvantages of supply chain management — Advantages of Supply Chain Management Cost Efficiency The first and foremost advantage of supply chain management is that it helps the company in achieving cost efficiency because it can lower various costs like transportation costs, warehousing, packaging costs, reduces wastage by timely delivery of goods and so on which ultimately helps the company in achieving cost efficiency which in turn increases the profitability of the company.

Advantages And Disadvantages Of Supply Chain Management

:max_bytes(150000):strip_icc()/terms_j_jit_V2-f07e0818e5e24ea38fabd8de814b22f8.jpg)

Pros and Cons of Supply Chain Management! Positive Cash Flow When business leaders make good decisions in terms of forecasting demand, resolving transportation issues, inventory, managing warehouses, and effectively dealing with disruptions. Organization Providing the critical success factors of cohesion, harmony and integration across organization entities - Level of cross functional integration is required to manage core processes effectively - Leverage cross-company skills and abilities - Performance measurement and reporting structure help to achieve objectives D. When your company uses supply chain management systems, it will be able to respond more quickly to changing economic conditions, emerging markets, and shorter product life cycles. Supply Chain Management helps to improve customer care service. Regardless of any doubt, any industry faces a range of challenges in the supply Pest Analysis Of Nordstrom 878 Words 4 Pages Slow speed will give more time while fast speed of technological disruption may give a business little time to cope and be profitable. Complicated Process of supply chain management involves numerous complexities as it involves several departments within the organization. Small businesses tend to design their own products but may not have the ability to manufacture; therefore they usually hire other companies to manufacture for them - this can be quite costly, so they commonly perform manufacturing on a large scale Hsc300 Unit 9 Final Paper 483 Words 2 Pages Support service must be provided through the developer or supplier of the technological product.

:max_bytes(150000):strip_icc()/terms_j_jit_V2-f07e0818e5e24ea38fabd8de814b22f8.jpg)