Sales and Operations Planning (S&OP) is a process used by organizations to align their sales, production, and inventory plans with their overall business strategy. Aggregate Sales and Operations Planning (AS&OP) is an extension of this process that takes into account the impact of these plans on the organization as a whole, rather than just at the individual product or department level.

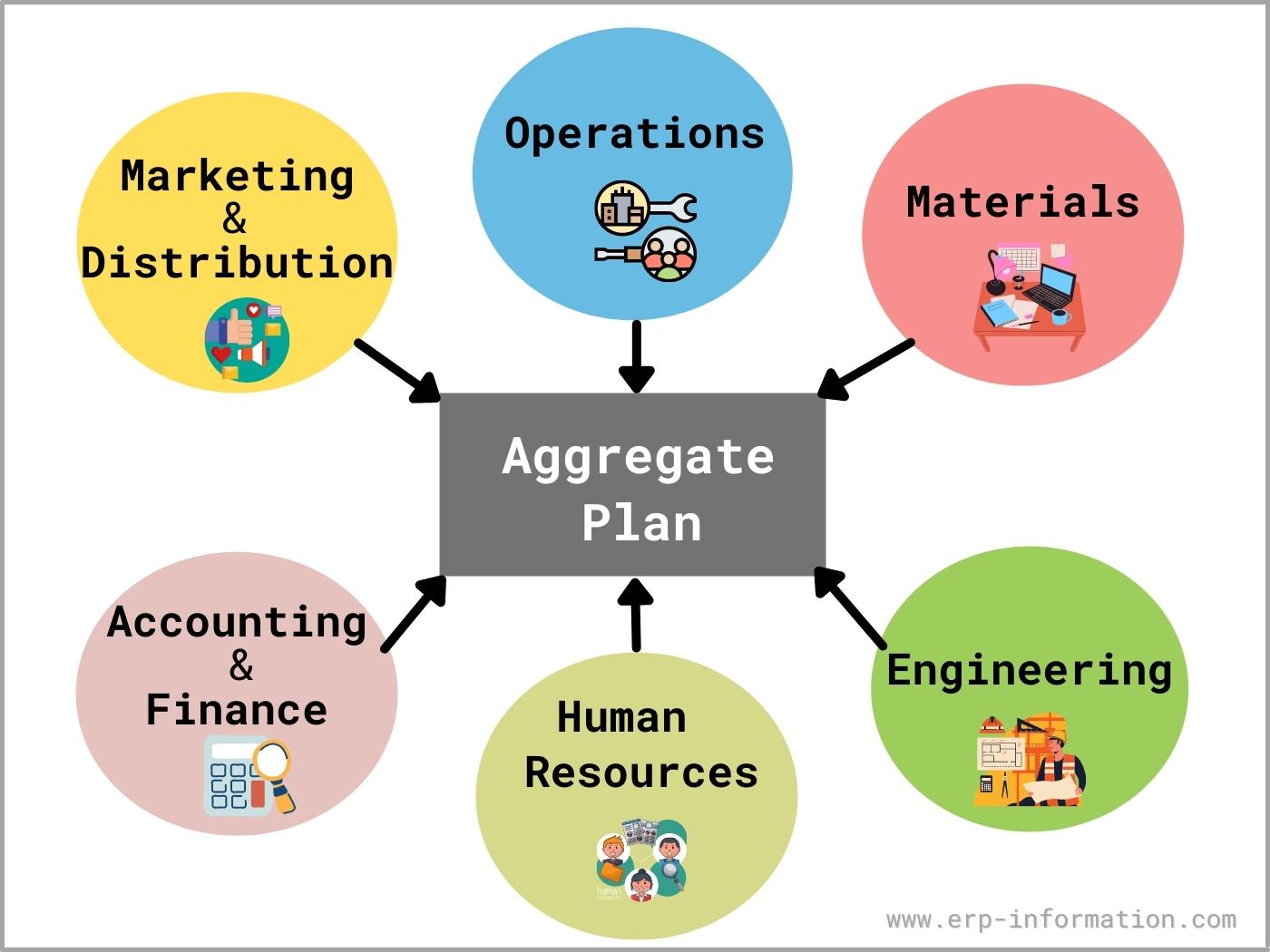

AS&OP involves the coordination of demand and supply at the aggregate level, allowing organizations to better manage their resources and make informed decisions about how to allocate them. This includes forecasting demand, determining production capacity, and adjusting inventory levels. By taking a holistic view of the organization, AS&OP can help ensure that all departments and functions are working towards the same goals and objectives.

One key element of AS&OP is the use of data and analytics to inform decision-making. This includes the use of statistical forecasting methods, such as exponential smoothing or seasonal decomposition, to predict future demand for products and services. It also involves the use of data on past performance, such as sales and production data, to identify trends and patterns that can help inform future planning.

AS&OP can help organizations to better manage their resources, optimize production and inventory levels, and reduce costs by avoiding overproduction or excess inventory. It can also help to improve customer service by ensuring that demand is met in a timely and efficient manner.

However, implementing AS&OP can be a complex and time-consuming process, and it requires the participation and buy-in of all departments and functions within the organization. It also requires strong communication and collaboration among these departments, as well as effective leadership to ensure that the AS&OP process is being followed and that any necessary adjustments are made in a timely manner.

In conclusion, Aggregate Sales and Operations Planning is a valuable process for organizations looking to align their plans with their overall business strategy and optimize the use of their resources. While implementing AS&OP can be challenging, the benefits it provides in terms of better resource management, cost reduction, and improved customer service make it well worth the effort.

Sales and Operations Planning (S&OP) 101

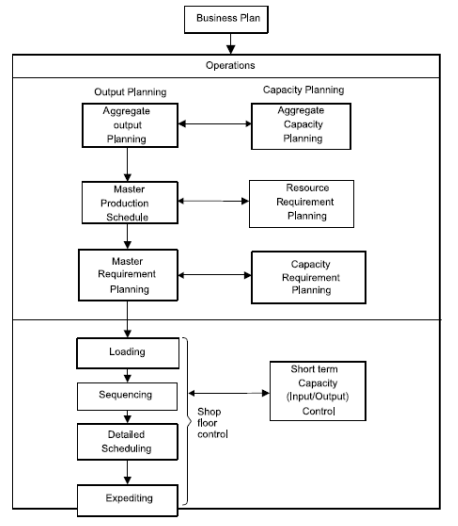

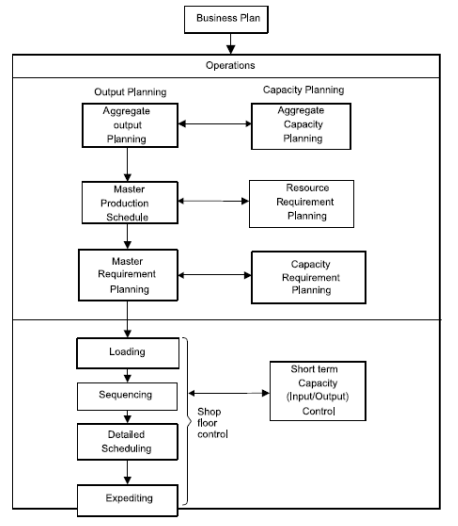

How are aggregate planning problems formulated and solved using Microsoft Excel? Aggregate Sales and Operations PlanningChapter 16 Bake a Cake Sales and Operations Planning Activities Long-range planning Greater than one year planning horizon Usually performed in annual increments Medium-range planning Six to eighteen months Usually with weekly, monthly or quarterly increments Short-range planning One day to less than six months Usually with weekly or daily increments 16-3 Pro ce ss p l n n i g a nLong range S u p p l n e tw o rk y pl nni g a n Fo re ca sti g a n d n dem and m anagem ent S tra te g i ca p a ci c ty pl nni g a n Sal s and e o p e ra ti n s o aggregate Aggregate Sa nn n p l l s i g operations ae pl n a plan Logistics Vehicle capacity planning Vehicle loading Vehicle dispatching Warehouse receipt planning Weekly workforce scheduling Daily workforce scheduling Services Medium range Manufacturing Master schedulingMaterial requirements planning Order schedulingShort range Required Inputs to the Production Planning System Competitors behavior External capacity Raw material availability Market demand Economic conditions External to firm Planning for production Current physical capacity Current workforce Inventory levels Activities required for production Internal to firm Aggregate Planning Capacity has a cost, lead times are greater than zero Aggregate planning: process by which a company determines levels of capacity, production, subcontracting, inventory, stockouts, and pricing over a specified time horizon goal is to maximize profit decisions made at a product family not SKU level time frame of 3 to 18 months Role of Aggregate Planning in a Supply Chain Specify operational parameters over the time horizon: production rate workforce overtime machine capacity level subcontracting backlog inventory on hand All supply chain stages should work together on an aggregate plan that will optimize supply chain performance The Aggregate Planning Problem Given the demand forecast for each period in the planning horizon, determine the production level, inventory level, and the capacity level for each period that maximizes the firms supply chains profit over the planning horizon Specify the planning horizon typically 3-18 months Specify the duration of each period Specify key information required to develop an aggregate plan Objectives of Aggregate Planning Objective of aggregate planning frequently is to minimize total cost over the planning horizon. This can be used as an alternative to hiring and firing employees. It is a nonprofit, educational organization for people employed in the supply management profession. Lower matinee movie prices, discount air fares, lowered weekend hotel rates, and higher weekend golf course green fees are examples of yield management. A successful answer to this question will also indicate that firms that are successful at using yield management have excellent forecasting skills and a well-trained staff who are skilled at dealing with customers who may be disappointed to find an activity that they have booked turns out to have no room for them. Ø The company looks at time in the aggregate — months, quarters, or seasons—rather than in days or hours. Finalize and implement Once the sales and operations plan has been approved, it is time for implementation.

What is Sales and Operations Planning (S&OP)

Consistent, structured meetings that require participant preparation , are held. Ø A company can aggregate its workforce in various ways as well, depending on its flexibility. FALSE Although a level strategy will maintain a stable workforce working at a constant output rate with shortages and surpluses are absorbed by fluctuating inventory levels, order backlogs, and lost sales, aggregate planning is necessary to establish the level at which the level strategy should be executed. This allows them to continuously match high-level strategy with day-to-day operational tactics in all departments. Our academic experts are ready and waiting to assist with any writing project you may have. Supply planning During supply planning, representatives from finance, operations, and materials to evaluate capacity. The first question has to be answered first because it is your leading indicator.