An air lift reactor is a type of bioreactor that uses air or other gases to circulate the liquid media in which biological reactions are taking place. This type of reactor is commonly used in the field of biotechnology for the production of various substances, such as enzymes, antibiotics, and biofuels.

One of the main advantages of using an air lift reactor is that it allows for the efficient mixing of the liquid media, which is important for maintaining the appropriate conditions for the biological reactions to occur. The air or gas used to circulate the liquid can also provide oxygen, which is essential for many types of microorganisms.

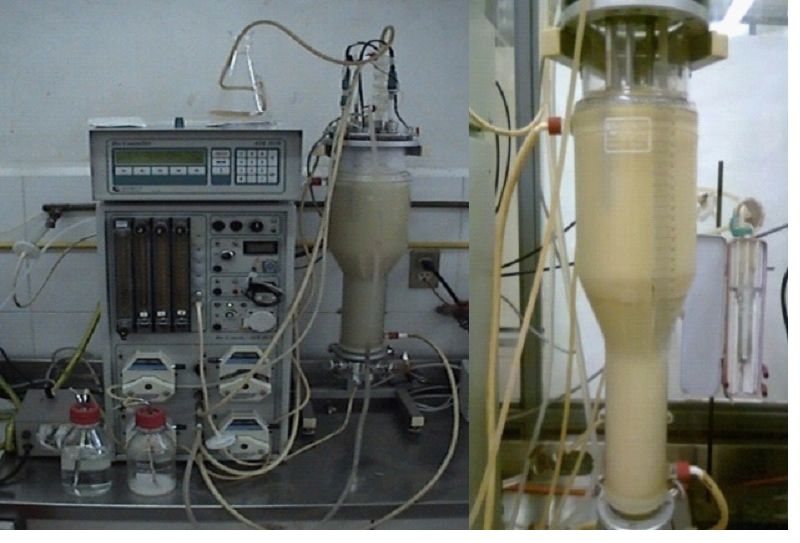

The design of an air lift reactor consists of a cylindrical vessel with a central sparger, which is a device that generates bubbles of air or gas. The sparger is typically located near the bottom of the vessel and is connected to a gas source. As the bubbles rise through the liquid, they create a flow of the liquid that circulates around the vessel. This circulation helps to evenly distribute the nutrients and other substances needed for the biological reactions to occur.

One of the key factors that affects the performance of an air lift reactor is the size of the bubbles produced by the sparger. If the bubbles are too large, they may not be able to effectively mix the liquid and may cause problems with the biological reactions. On the other hand, if the bubbles are too small, they may not provide sufficient oxygen for the microorganisms.

In addition to their use in biotechnology, air lift reactors have also been used in a variety of other fields, including wastewater treatment, aquaculture, and even space exploration. Their versatility and efficiency have made them a popular choice for many applications.

Overall, the air lift reactor is a valuable tool in the field of biotechnology and has a wide range of potential applications. Its ability to effectively mix and circulate liquids, as well as provide oxygen, makes it an important tool for many biological reactions and processes.