Asphalt paving is a common method used to pave roads, driveways, and other surfaces. It is a durable and cost-effective option that provides a smooth and safe surface for vehicles to travel on. There are several different methods for paving with asphalt, each with its own unique set of advantages and disadvantages.

One common method for paving with asphalt is called hot mix asphalt (HMA). This method involves heating the asphalt binder to a temperature of around 300°F and mixing it with aggregate materials, such as sand and gravel. The hot mix is then placed onto the surface to be paved and compacted using a roller or a paver. HMA is a versatile paving option that can be used in a wide range of applications, including roads, driveways, parking lots, and more. One advantage of HMA is that it can be placed and compacted in a single pass, which helps to reduce construction time and costs. However, HMA requires specialized equipment and trained personnel to handle the hot mix, which can be a disadvantage.

Another method for paving with asphalt is called cold mix asphalt (CMA). This method involves mixing the asphalt binder with aggregate materials at room temperature, rather than heating it. CMA can be used to patch or repair areas of asphalt pavement, or it can be used as a temporary surface for construction projects. One advantage of CMA is that it can be applied in a variety of weather conditions, including cold and wet conditions. It is also a more cost-effective option than HMA, as it does not require specialized equipment or trained personnel. However, CMA is not as durable as HMA and is not suitable for use in high-traffic areas.

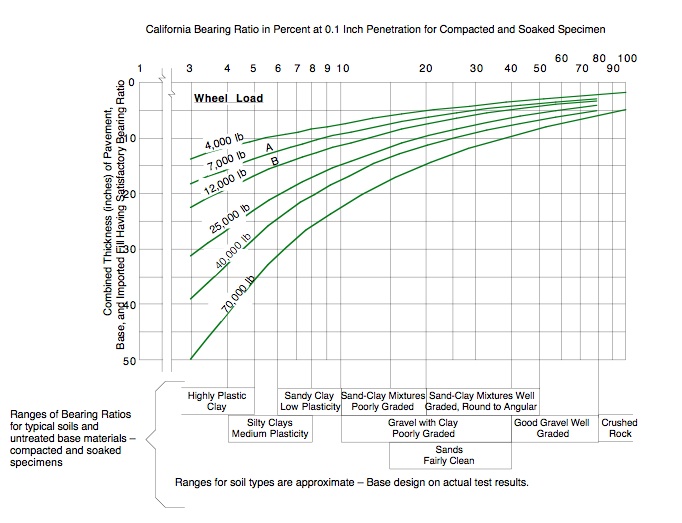

A third method for paving with asphalt is called full-depth asphalt (FDA). This method involves placing the asphalt mix in layers, starting with a base layer and building up to the surface layer. FDA is a long-lasting paving option that is suitable for use in high-traffic areas and heavy load conditions. It provides a strong, stable surface that can withstand the weight of heavy vehicles and is resistant to cracking and other forms of damage. However, FDA is more labor-intensive and time-consuming to install than other asphalt paving methods, and it requires specialized equipment and trained personnel.

In conclusion, there are several different methods for paving with asphalt, each with its own unique set of advantages and disadvantages. Hot mix asphalt is a versatile option that can be used in a wide range of applications, but it requires specialized equipment and trained personnel. Cold mix asphalt is a more cost-effective option that can be applied in a variety of weather conditions, but it is not as durable as HMA. Full-depth asphalt is a long-lasting option that is suitable for use in high-traffic areas, but it is more labor-intensive and time-consuming to install. Ultimately, the best asphalt paving method will depend on the specific needs and requirements of the project.