An axle friction lab report is a document that presents the results of a laboratory experiment that aims to measure the frictional forces acting on an axle. The purpose of this experiment is to understand the behavior of friction in a real-world situation, as well as to determine the factors that influence the amount of friction present.

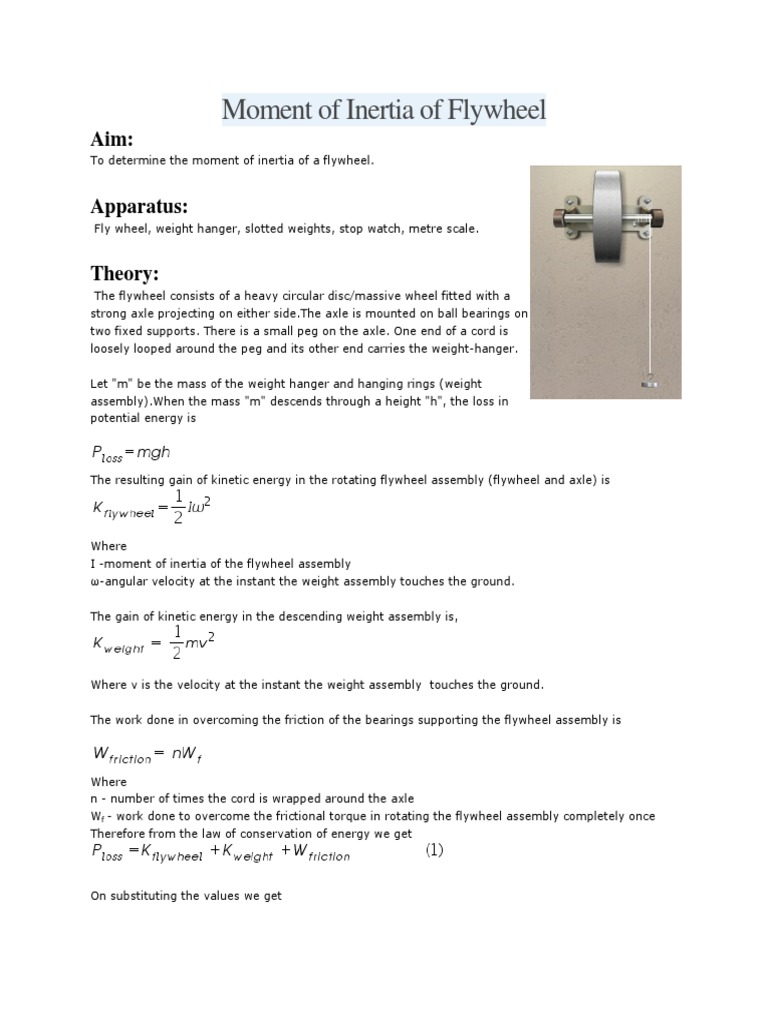

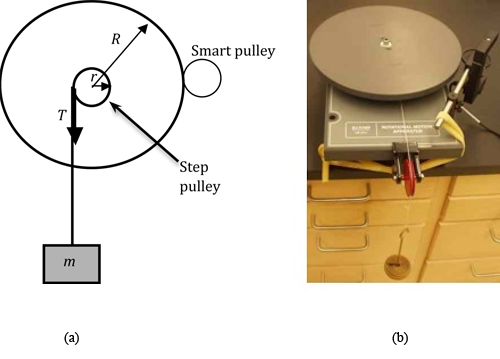

To conduct the experiment, a set-up is required that includes an axle, a load, and a means of measuring the frictional forces. The axle is typically made of metal and is supported by bearings, which allow it to rotate freely. The load is applied to the axle by attaching weights or other objects to the end of the axle. The frictional forces acting on the axle can be measured using a variety of methods, such as a spring scale or a load cell.

In the experiment, the load is gradually increased and the frictional forces acting on the axle are measured at each increment. This allows the relationship between the load and the friction to be determined. The results of the experiment can then be plotted on a graph to visualize this relationship.

There are several factors that can influence the amount of friction present in an axle. These include the material of the axle, the surface roughness of the axle, and the type of lubrication used. In the lab report, these factors should be discussed and their impact on the results of the experiment should be analyzed.

In addition to presenting the results of the experiment, a good lab report should also include a discussion section. In this section, the results of the experiment should be interpreted and compared to theoretical predictions. Any discrepancies between the results and the predictions should be explained, and the limitations of the experiment should be acknowledged.

Overall, an axle friction lab report is a valuable tool for understanding the behavior of friction and the factors that influence it. By conducting this experiment and presenting the results in a clear and concise manner, students can gain a deeper understanding of this important physical concept.