Barilla Spa is a leading Italian pasta company that was founded in 1877 by Pietro Barilla. The company has a strong global presence, with its products sold in more than 100 countries around the world. However, in the late 1980s, Barilla began to experience supply chain problems that were causing significant disruptions and inefficiencies. In response, the company implemented a new supply chain management system called the "Just-In-Time Distribution System" (JITD).

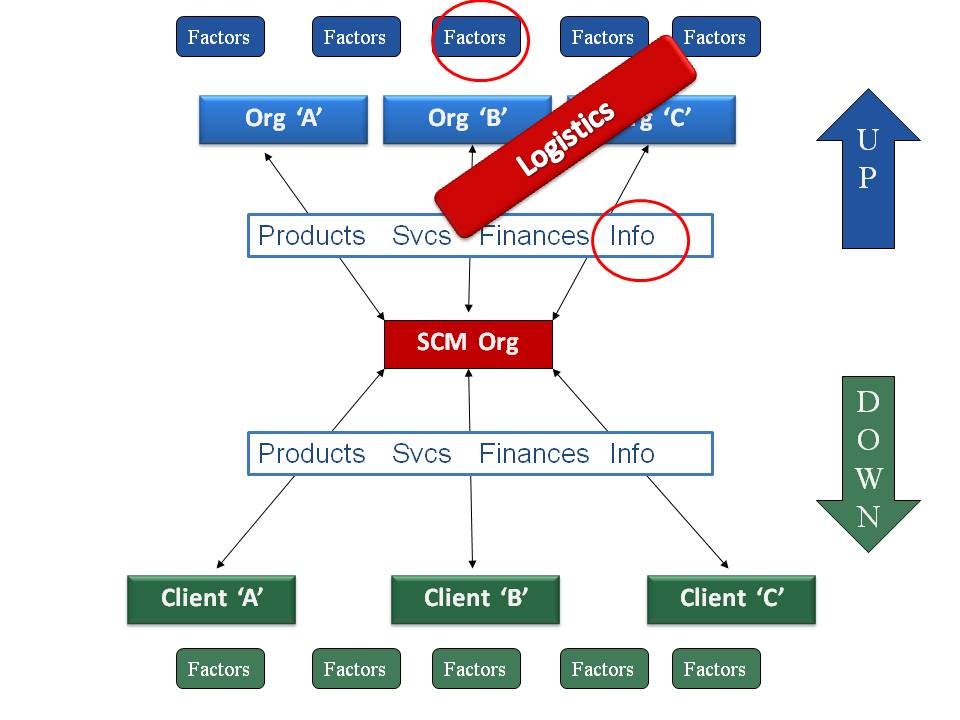

The JITD system was designed to improve the efficiency of Barilla's supply chain by reducing inventory levels and increasing the responsiveness of the system to customer demand. It relied on the use of advanced computer systems and real-time data to monitor and control the flow of materials and products through the supply chain.

One key element of the JITD system was the use of "pull" signals, which were used to trigger the production and delivery of products based on actual customer orders, rather than relying on forecasts of future demand. This meant that Barilla could produce and deliver products more quickly and efficiently, as it was only producing what was actually needed at any given time.

The JITD system also included the use of cross-docking, which is a logistics practice in which incoming products are immediately shipped out to customers without being stored in a warehouse. This helped to reduce inventory levels and improve the speed of delivery.

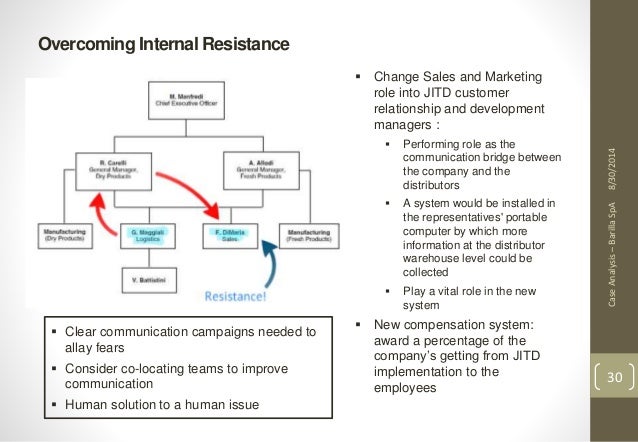

Overall, the JITD system was successful in improving the efficiency of Barilla's supply chain and reducing costs. However, it also had some negative impacts, particularly on the company's relationships with its customers. Some customers complained that the JITD system was inflexible and did not allow for changes in orders or delivery schedules.

To address these concerns, Barilla implemented a new system called the "Distributed Autonomous Replenishment System" (DARS), which was designed to be more flexible and responsive to the needs of customers. DARS allowed customers to place orders through a web-based portal, which gave them more control over the timing and quantity of their orders.

In conclusion, the implementation of the JITD and DARS systems at Barilla was successful in improving the efficiency and responsiveness of the company's supply chain. However, it also highlighted the importance of considering the needs and preferences of customers in the design and management of supply chain systems.

Barilla Spa is an Italian pasta manufacturer that experienced significant supply chain issues in the 1990s. These issues included unpredictable demand from customers, inefficient production processes, and poor inventory management, which led to high levels of waste and customer dissatisfaction. In order to address these issues, Barilla implemented a number of changes to its supply chain, including the implementation of a just-in-time (JIT) system and the creation of a demand-driven supply chain.

One of the key changes that Barilla made was the implementation of a JIT system. In a JIT system, suppliers only produce and deliver the materials and products that are needed by the customer at the time they are needed, rather than producing and holding large inventories. This allows for a more efficient and cost-effective production process, as it reduces the need for expensive storage and minimizes waste.

In order to implement the JIT system, Barilla had to make a number of changes to its supply chain. First, it had to establish more reliable and consistent demand forecasts. To do this, it implemented a demand-driven supply chain, in which demand from customers was used to drive production and inventory levels. This allowed Barilla to better predict demand and adjust production accordingly.

Additionally, Barilla implemented a number of other changes to its supply chain in order to support the JIT system. These included implementing a more efficient production process, improving communication and coordination with suppliers, and implementing a new IT system to better manage inventory and production.

Overall, the changes implemented by Barilla had a significant impact on the company's supply chain. These changes allowed the company to better predict and meet customer demand, reduce waste and costs, and improve overall efficiency. As a result, Barilla was able to significantly improve customer satisfaction and increase its market share.