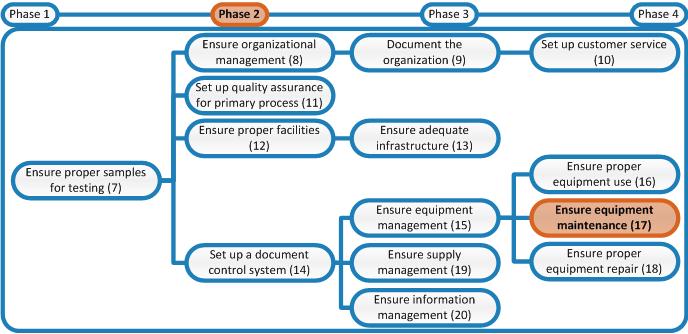

Calibration and maintenance are important practices in a wide range of industries, including manufacturing, healthcare, and scientific research. They are essential for ensuring that equipment and systems are operating accurately and reliably, and they can help prevent costly breakdowns and accidents.

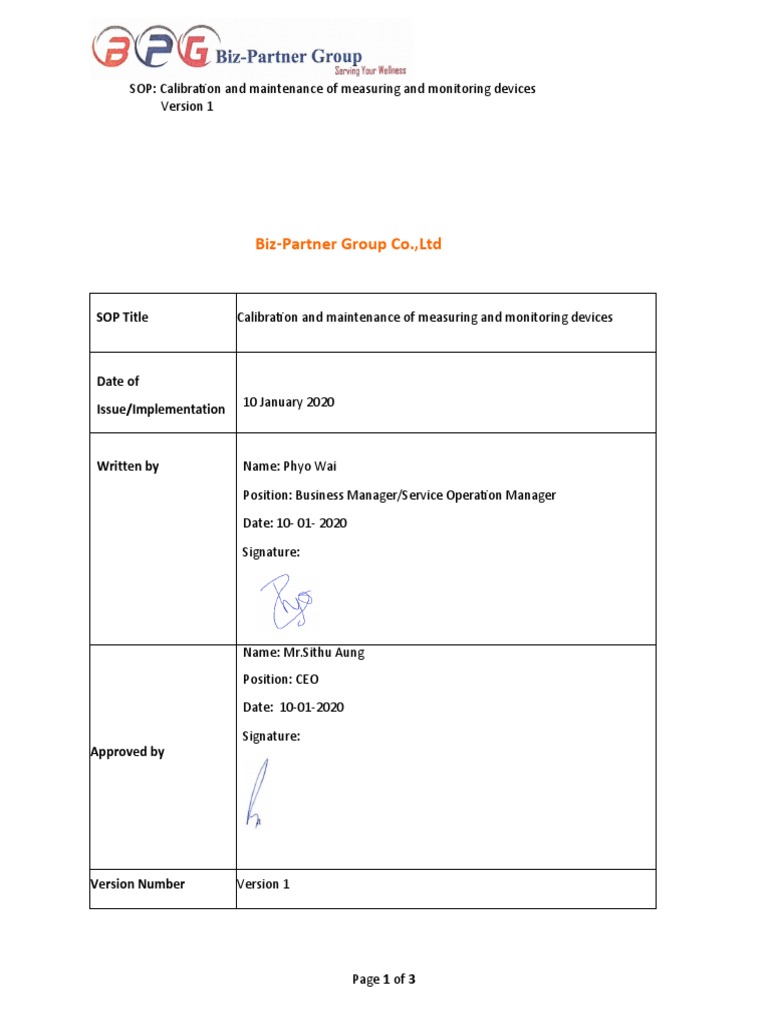

Calibration involves adjusting a device or system to meet a specific standard or specification. This is typically done using specialized equipment and procedures, and it may be necessary to recalibrate a device periodically to ensure that it remains accurate over time. Calibration is important for a number of reasons, including ensuring the accuracy of measurements, improving the reliability of test results, and maintaining safety standards.

Maintenance, on the other hand, involves regularly inspecting and servicing equipment to ensure that it is in good working order. This can include cleaning and lubricating components, replacing worn or damaged parts, and performing routine checks to identify potential problems. Regular maintenance can help extend the lifespan of equipment, reduce downtime and maintenance costs, and improve overall performance.

Both calibration and maintenance are critical for the smooth operation of any facility or organization. Neglecting these practices can lead to a range of problems, including inaccurate measurements, reduced productivity, and safety hazards. To ensure that equipment is operating at its best, it is important to establish a regular schedule for calibration and maintenance, and to follow best practices and guidelines to ensure that these activities are carried out correctly.

In summary, calibration and maintenance are essential practices that help ensure the accuracy and reliability of equipment and systems. By regularly calibrating and maintaining equipment, organizations can improve productivity, reduce downtime and maintenance costs, and maintain safety standards. These practices are critical for the smooth operation of any facility or organization, and should be given the attention and resources they deserve.