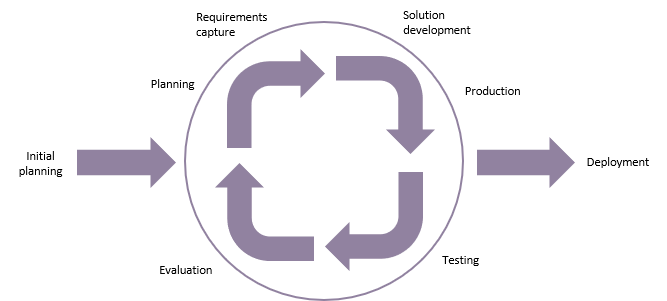

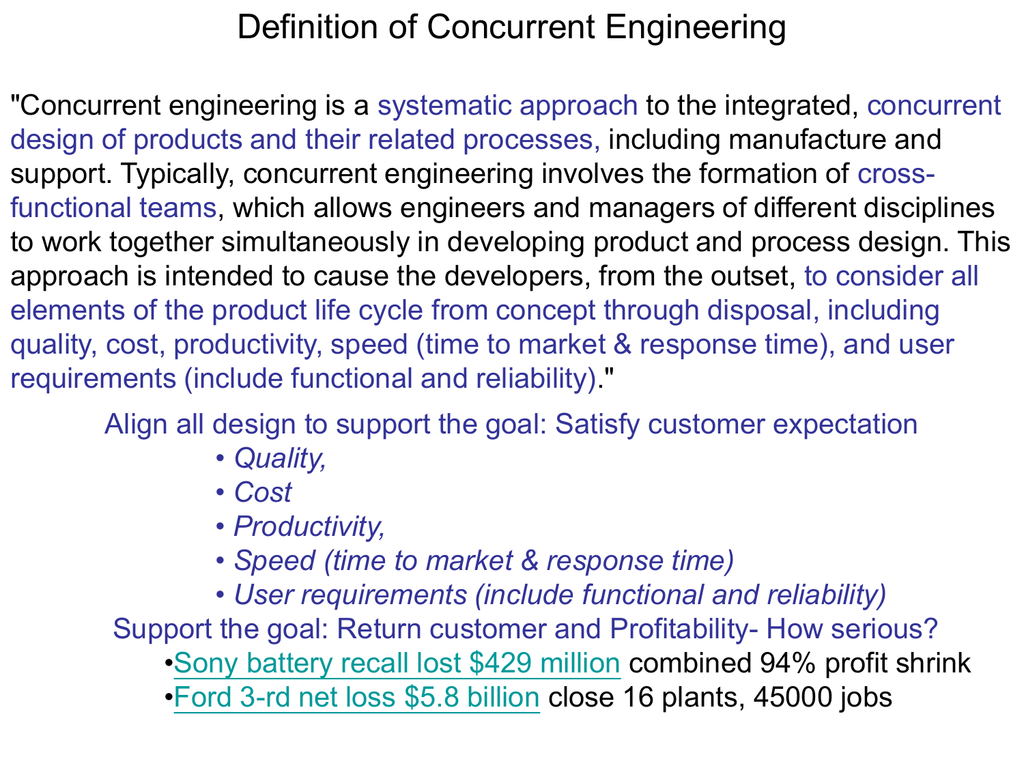

Concurrent engineering is a concept that has been embraced by many organizations in recent years as a way to improve efficiency, reduce costs, and increase competitiveness. It is a method of designing and developing products that involves all relevant stakeholders in the process from the very beginning, rather than sequentially. This approach allows for the identification and resolution of problems and challenges early on in the development process, rather than after the product has already been designed and built.

The goal of concurrent engineering is to optimize the design process by considering all aspects of the product development simultaneously. This includes technical considerations such as engineering and manufacturing, as well as commercial and market considerations such as cost, time to market, and customer needs. By bringing all of these stakeholders together from the start, concurrent engineering allows for a more holistic and integrated approach to product development.

One of the key benefits of concurrent engineering is that it allows for a more efficient use of resources. By involving all relevant stakeholders in the process from the beginning, potential problems and challenges can be identified and addressed early on, rather than after the product has already been designed and built. This can save time and money by reducing the need for rework and redesign.

Another benefit of concurrent engineering is that it allows for the development of products that are more closely aligned with the needs of the customer. By involving all relevant stakeholders in the process from the start, the product can be designed to meet the specific needs and requirements of the customer, rather than being developed in a vacuum and then trying to fit the customer's needs afterwards.

There are several key factors that are critical to the success of concurrent engineering. One of these is effective communication and collaboration among all relevant stakeholders. It is important that all stakeholders are able to share ideas, information, and feedback in a timely and effective manner. This requires strong leadership and the ability to foster a culture of collaboration and teamwork.

Another key factor is the use of appropriate tools and technologies to support the concurrent engineering process. This may include computer-aided design (CAD) software, project management tools, and other technologies that enable real-time collaboration and communication among all stakeholders.

In conclusion, concurrent engineering is a concept that has the potential to significantly improve the efficiency, cost-effectiveness, and competitiveness of product development. By involving all relevant stakeholders in the process from the very beginning, it allows for the identification and resolution of problems and challenges early on, and enables the development of products that are more closely aligned with the needs of the customer. To be successful, however, it requires effective communication and collaboration among all stakeholders, as well as the use of appropriate tools and technologies to support the process.