A conveyor belt is a mechanical device used to transport materials or products from one place to another. It consists of a continuously moving belt, powered by a motor, that is supported by rollers or a flat surface. The motor that drives the conveyor belt is an important component, as it determines the speed and power of the belt. Therefore, proper motor control is essential for the smooth and efficient operation of the conveyor belt.

There are various methods of controlling the motor of a conveyor belt, and the most suitable method will depend on the specific requirements of the application. Some common methods include:

Variable frequency drives (VFDs): These are electronic devices that are used to control the speed of an induction motor by varying the frequency of the power supply. VFDs are commonly used in conveyor belts because they offer precise control and energy efficiency. They also allow the speed of the belt to be easily adjusted to match the requirements of the material being transported.

Mechanical speed control: This method involves using a mechanical device, such as a pulley or gear system, to control the speed of the motor. While this method is simple and inexpensive, it is not as precise or energy efficient as VFDs.

PLC (Programmable Logic Controller) control: A PLC is a digital computer used for automation of electromechanical processes. It can be programmed to control the conveyor belt motor based on input signals from sensors, such as weight sensors or proximity sensors. This allows for precise control of the belt and can also be used to automate processes such as sorting or counting.

In addition to the above methods, there are also various sensors and control systems that can be used to monitor and optimize the performance of the conveyor belt motor. For example, temperature sensors can be used to detect overheating and prevent damage to the motor, while current sensors can be used to monitor the load on the motor and adjust the speed accordingly.

In conclusion, proper motor control is essential for the smooth and efficient operation of a conveyor belt. There are various methods available for controlling the motor, and the most suitable method will depend on the specific requirements of the application. By using the appropriate control method and monitoring systems, the performance of the conveyor belt can be optimized and downtime minimized.

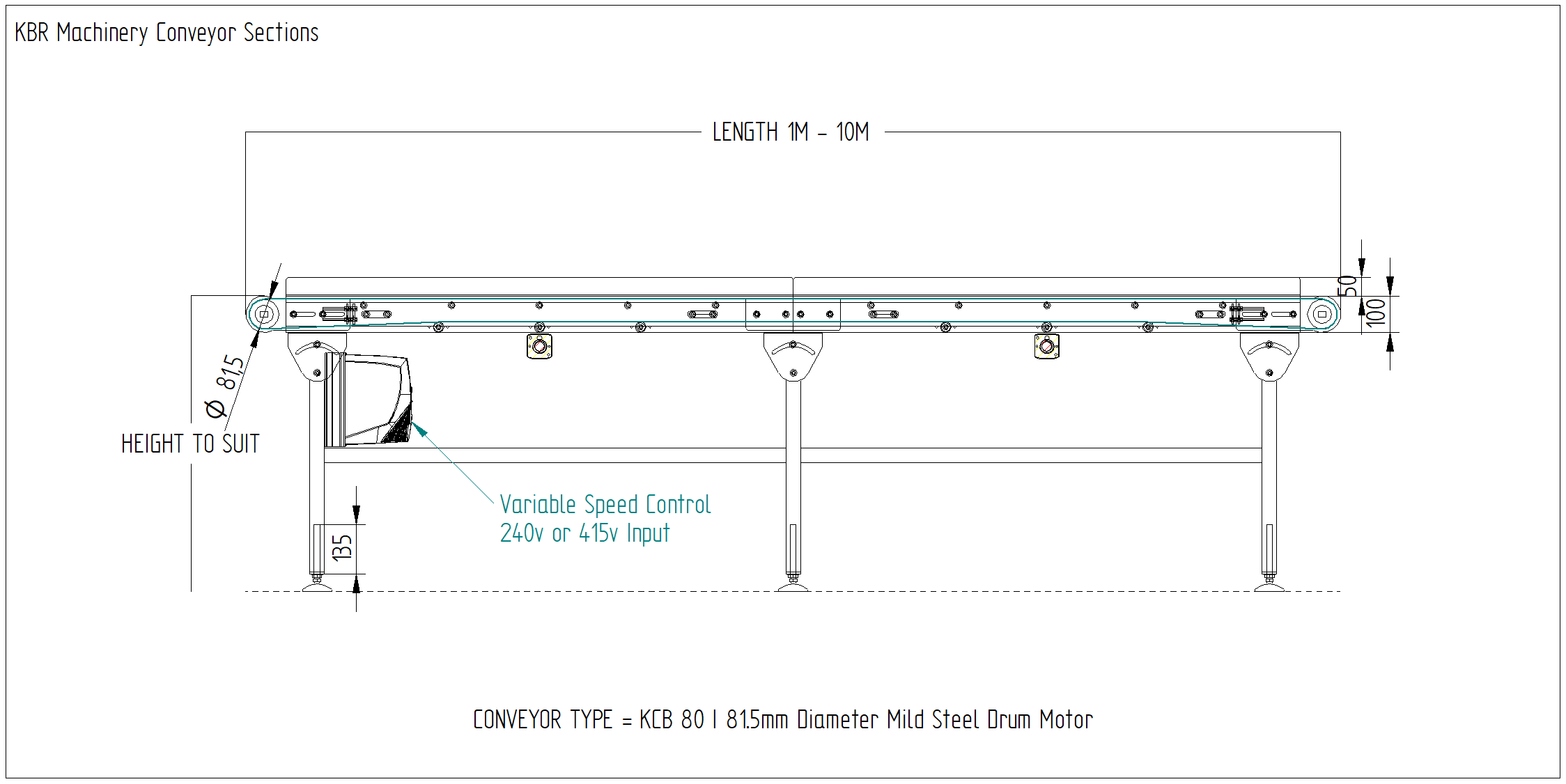

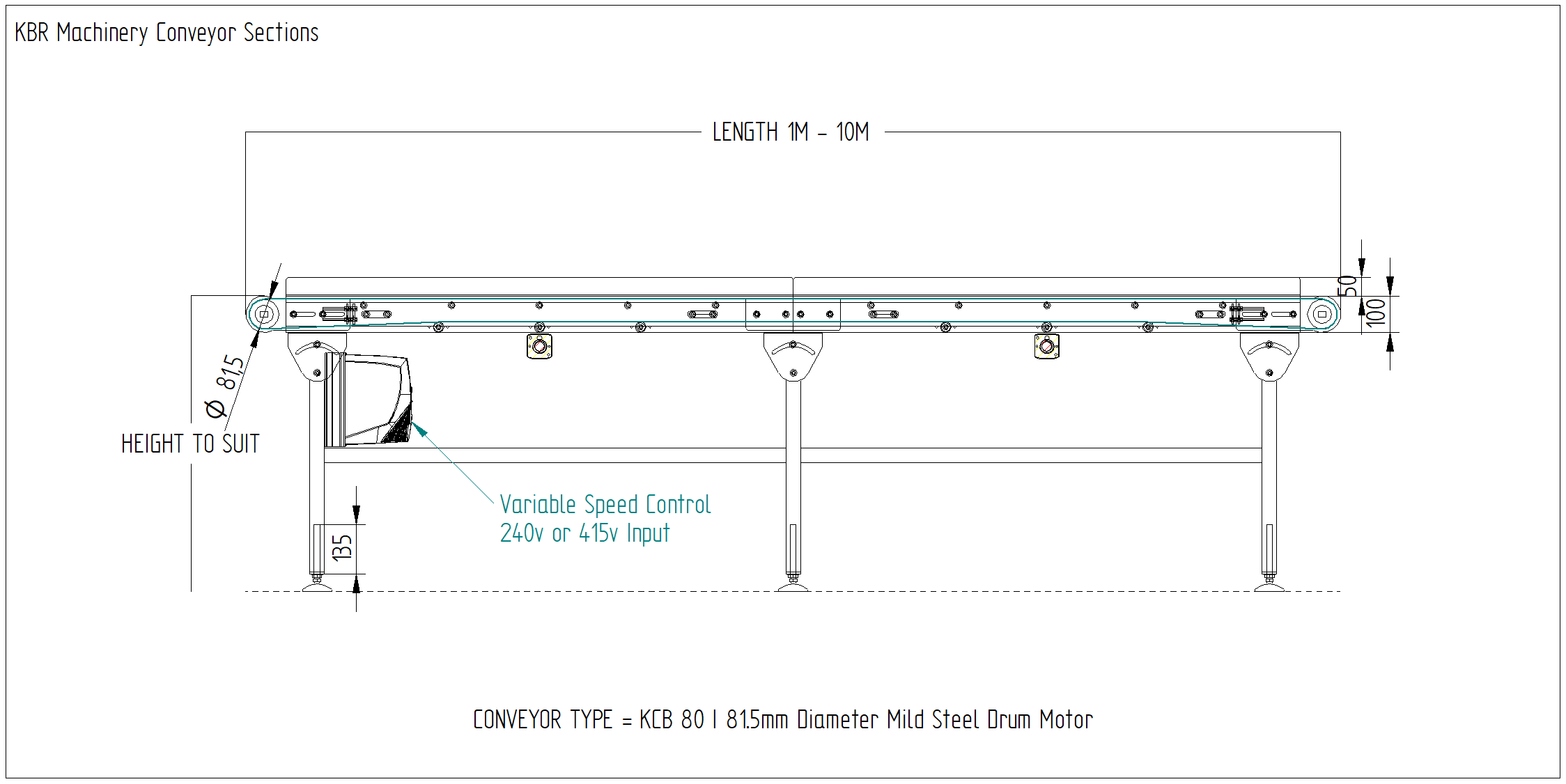

MODULAR & PORTABLE CONVEYOR BELT. SPEED CONTROL BY ARDUINO : 5 Steps

This whole processruns on single conveyor belt. Constantly improve has gradually developed from completing the transportation within the workshop to completing the material handling within enterprises, between enterprises and even between cities, and has become an indispensable part of the mechanization and automation of the material handling system. For precise positioning Oriental Motor's stepper or servo motor packages are ideal. The servo motor has restrictions on permissible load inertia, but the geared type can be used to greatly increase the load size that can be driven. These highly visible "Push to activate" and "Pull to reset" mushroom headed E-Stops switched conform to EN418 for machine safety. Generally speaking, there are 2 well defined groups of this kind of devices: Ready to use usually very robust , "good looking" and the "DIY" ones made of household stuff.

PLC Conveyor Motor Ladder Logic

If possible from a car, The bigger , the better this provides a more regular and flat surface than smaller ones i. It consists of drive mechanisms such as Figure 1. And then stops dropping items. OME Motors designs and builds conveyor belt motors capable of supporting these processes. Cut the ends of the band in an approximate angle of 45 degrees, so it will have less resistance and smoother travel when the joint approaches to an axle. The controller provides seamless audio communication between the two communication lines, controls and monitors pre-start alarms via a digital communication link. In 1913, conveyors were first used in the manufacturing industry when Henry Ford introduced conveyor belts in the assembly lines of Ford Motor Company.

Conveyor Belt controller

Belt Conveyor System A belt conveyor uses a belt to transport material from one point to another. Solid shaft and hollow shaft models are available. So depending upon this input and output we have to design a circuit that will control this conveyor belt. Use sensors to create systems that shut-off when items are delivered and then restart as they are removed. A motorized roller conveyor system. A wide range of gearing options are available: Spur, Taper Hobbed, Planetary and Harmonic gearheads. This phenomena happens to stepper motors when the pulse train frequency is near their natural resonance frequency.

Belt Conveyor

Or, a bearing can be used on one end with a sprocket at another end. Since 1957, several other conveyor systems have been implemented throughout factories worldwide. Just take an example of any bottling plant then in this case the bottles are moving on belt one by one and at one place they are filled, atanother place they are sealed, then labeling and finely packaging in a bunch on 10, 20 or 50 likewise. Factory Automation Network - Use of a network converter sold separately enables support with CC-Link, MECHATROLINK or EtherCAT communication. A History of Conveyor Systems The conveyor systems were first developed in 1892 by Thomas Robins for the coal industry. The main idea behind this invention was to assist material movement with minimum or zero human involvement. All four sensor outputs are connected with P3 pins P3.

Conveyor belt motor for uninterrupted use from OME Motors

Right-Angle Gearheads are suitable for applications where space saving is required by allowing the motor to be mounted at a right-angle to the conveyor. The protocol supports Modbus RTU , enable connection with devices such as a touch screen HMI or PCs. In this project the additional 16 12 for bearings, 2 for motor bracket and 2 for the control box T slot nuts must be placed inside the slots before building the frame. To join the ends of the band, use a rubber glue again, don't use super glue or the joint will be too rigid. This means that up to four brushless DC motors and four area sensors can be connected and controlled at the same time. Along with main function entire program is a combination of 5 different functions. In fact, they are particularly suitable for operating under difficult conditions and created to work in combination with tables, working and transport rollers, but also with laminators or other equipment used in steel plants.

Conveyor Motor Controls

There are four outputs and they are from various sensors placed on belt. For example, a conveyor belt may transport a container from filling machines to the packaging machine in the packaging department. In almost all the manufacturing industries where ever there is complete assembly line automation like bottling plant, chemical industries, food processing and packaging industries a conveyor belt is ultimate and widely used option. Controllers and human-machine interfaces HMIs :The main controller and HMI control the conveyor system operation. VFDs and motors: Proximity sensors: Figure 5. Introduction of conveyor belt equipment The conveyor belt is affected by the technological progress of machinery manufacturing, motor, chemical industry and metallurgical industry. In 1901, Swedish Company Figure 2.

Conveyor System

Remote Stop Switches can be provided with the Safe Conveyor drive systems. These types are useful for highly automated facilities. Speed Control Conveyor Belt Systems For conveyors where the speed needs to controlled or vary during operation Oriental Motor offers easy-to-use By combining a control circuit with the motor, speed changes can be performed. For example, in food and pharmaceutical product filling operations, the material is transferred to the filling station through conveyor systems. The communication protocol of the master controller, Factory Automation FA network, is converted to Oriental Motor's own RS-485 communication protocol.