Cook Composites & Polymers Co. (CCP) is a leading manufacturer of advanced composite materials and polymers. Founded in 1968, CCP has a long history of innovation and excellence in the industry.

CCP's products are used in a wide range of applications, including transportation, construction, industrial, and recreational markets. The company's composite materials are used in the manufacturing of boats, car parts, wind turbine blades, and other products that require strength, durability, and lightweight properties. Its polymers are used in the production of coatings, adhesives, and sealants for various industries.

One of the key benefits of CCP's products is their ability to perform in harsh environments. The company's composite materials are resistant to extreme temperatures, UV radiation, and chemical exposure, making them suitable for use in outdoor applications. Additionally, CCP's polymers have excellent adhesion and bonding properties, which make them ideal for use in construction and other industries that require strong and durable materials.

CCP is committed to sustainability and is constantly seeking ways to reduce its environmental impact. The company's composite materials are made using renewable resources and are fully recyclable, making them a more environmentally friendly alternative to traditional materials. CCP's polymers are also designed to be energy efficient and reduce emissions during the manufacturing process.

In conclusion, Cook Composites & Polymers Co. is a leading manufacturer of advanced composite materials and polymers that are used in a wide range of applications. The company's products are known for their strength, durability, and ability to perform in harsh environments, and CCP is committed to sustainability and reducing its environmental impact.

Dealing With Emissions: Cook Composites and Polymers Co.

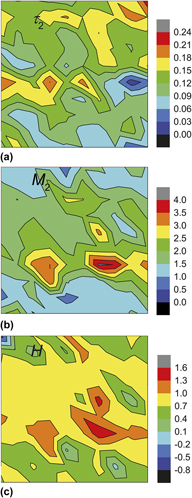

Depending on the level ofmethyl ethyl ketone peroxide used, the solid wastemay be classified as hazardous because of toxicity. To alter the flammabilitycharacteristics of a resin, acids such as chlorendicanhydride and tetrabromophthalic anhydride are used. Somemonomers and cleanup solvents used may havehealth effects. This testimony, however, was not given nor was the president's view stated until the lawsuit commenced. FuelQuantities of a fuel source are requiredfor a fire. With the implementation of new standards and regulations, we all are challenged with making the transition to new processes and materials. By properly handling catalysts and accelerators,controlling vapors, and keeping the shop safelyclean, much can be done to reduce the risk of fire.

Cook Composites And Polymers Co in Oxnard, CA

Unauthorized Practice of Law Committee, 883 S. This is not meant as a recommendationor endorsement of any of these references or services. The loss of styrene atthis point is controlled by temperature, method ofatomization, spray distance, and the degree ofbreakup atomization. This approach benefited the company and was different from the waste exchange method that used open memberships. Consult local insuranceinspection bureau and fire authorities for guidance. Seller shall not be liable for any injury, loss or damage, resulting from the handling or use of the product shipped hereunder whether in the manufacturing process or otherwise.

History

See National Environmental Service Co. We look to these circumstances merely to assist us in understanding the object and purpose of the contractual language the parties chose. The record, however, does not support Westlake's factual assertions. Where contact isunavoidable, protective equipment clothing, gloves,etc. Care and caution must be used with these materialsand the materials used in their application andremoval. Peroxides containchemically combined oxygen which can be easilyliberated for combustion by heat, chemical reaction,decomposition, contamination, etc.

COOK COMPOSITES INC v. WESTLAKE STYRENE CORPORATION

In construing the contract, we consider how a reasonable person would have used and understood the language, by pondering the circumstances surrounding the contract's negotiation, and by considering the purposes which the parties intended to accomplish by entering into the contract. A very small amount of peroxide initiator can makedrastic changes in the physical properties of a resinor gel coat. All possible sources of static discharge should beeliminated through adequate grounding or othermeasures. Contact the supplier to request a ProductStewardship visit. Depending on the application equipment, thetemperature, and gel time, gel coats may lose 20 to25 percent of the pounds sprayed, or up to 65percent of the monomer s present.