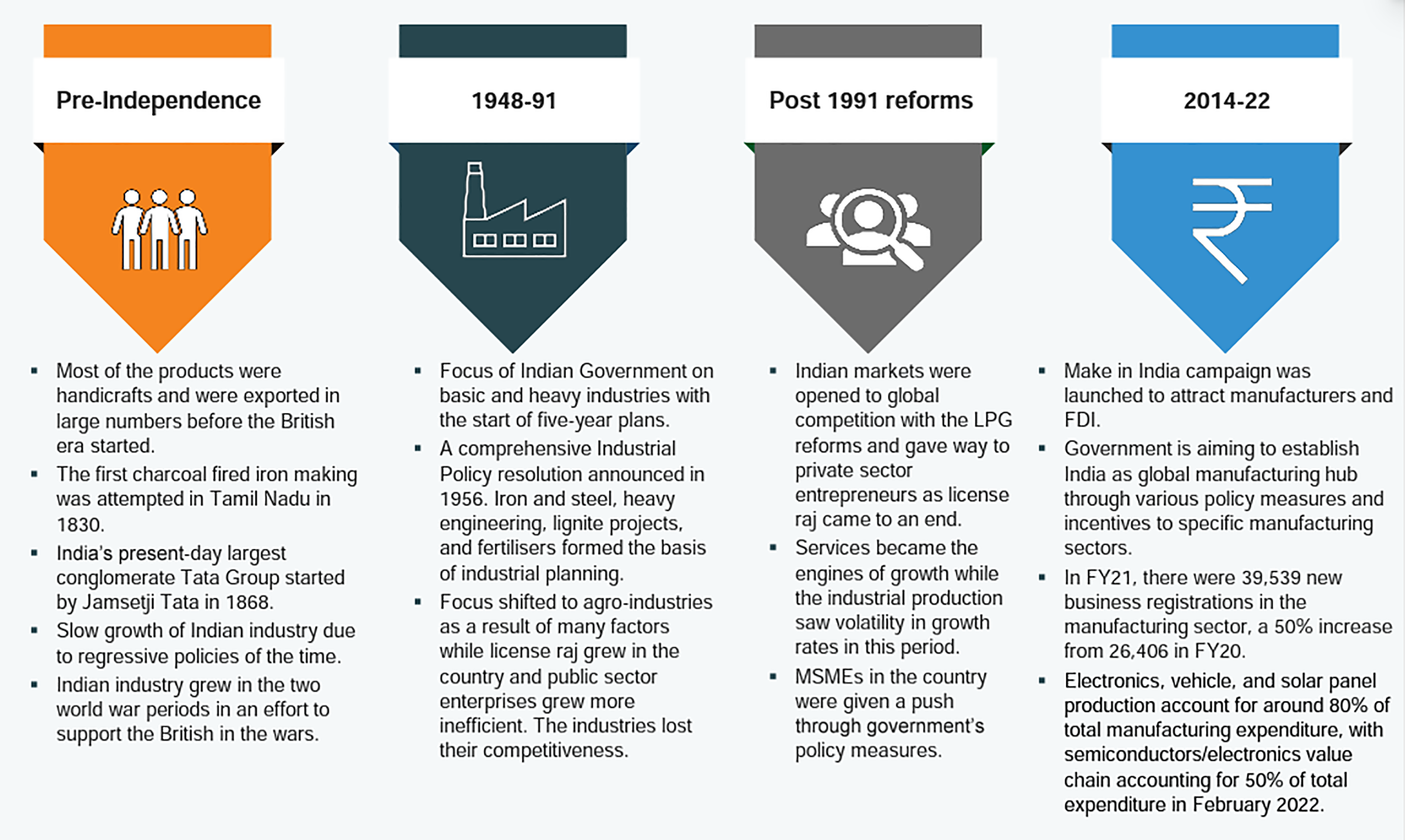

The steel industry in India has a long and storied history, with roots dating back to the early 20th century. In the early years, the industry was characterized by small-scale production and a reliance on imported technology. However, over the years, the industry has undergone significant development and growth, becoming a major player in the global steel market.

The early years of the steel industry in India were marked by a lack of infrastructure and technological advancements. Most steel production was carried out in small-scale units, with limited capacity and efficiency. The industry relied heavily on imported technology and equipment, which made it difficult for local producers to compete with international players.

However, the situation began to change in the 1960s, when the government implemented a series of policies aimed at promoting the development of the steel industry. One of the key measures was the establishment of the Steel Authority of India (SAIL), a state-owned enterprise that was responsible for modernizing and expanding the steel industry. SAIL was given the task of setting up large-scale steel plants and implementing new technologies, such as the Basic Oxygen Furnace (BOF) and the Continuous Casting (CC) process.

Over the years, SAIL has played a key role in the development of the steel industry in India, building a number of large-scale steel plants and introducing new technologies. In addition to SAIL, there are also several private sector companies that have contributed to the growth of the industry, including Tata Steel, JSW Steel, and ArcelorMittal. These companies have invested heavily in modernizing their facilities and adopting new technologies, which has helped to increase efficiency and competitiveness.

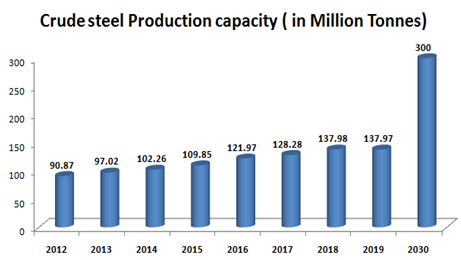

In recent years, the steel industry in India has experienced rapid growth, with production increasing by more than tenfold since the 1960s. Today, India is the third-largest steel producer in the world, with an annual production of around 110 million tons. The industry is a major contributor to the country's economy, providing employment to millions of people and contributing to the development of infrastructure and manufacturing.

There are several factors that have contributed to the development of the steel industry in India. One of the key drivers has been the government's commitment to the sector, with policies aimed at promoting investment and technological advancement. In addition, the availability of raw materials, such as iron ore and coal, has also played a role in the growth of the industry. Finally, the increasing demand for steel in domestic and international markets has also helped to drive the industry's growth.

Overall, the development of the steel industry in India has been a success story, with the industry undergoing significant growth and modernization over the past few decades. Today, India is a major player in the global steel market, and the industry continues to be an important contributor to the country's economy.