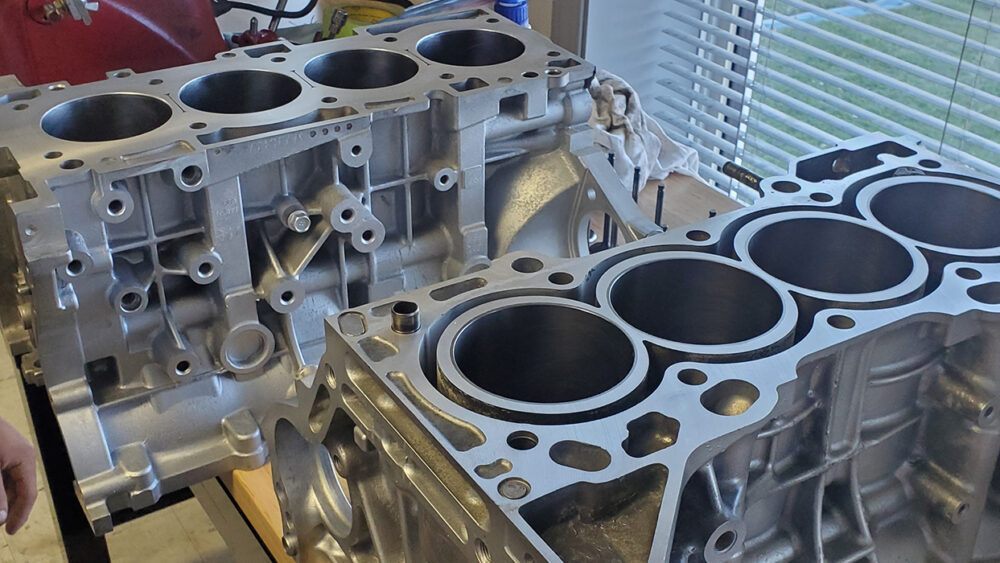

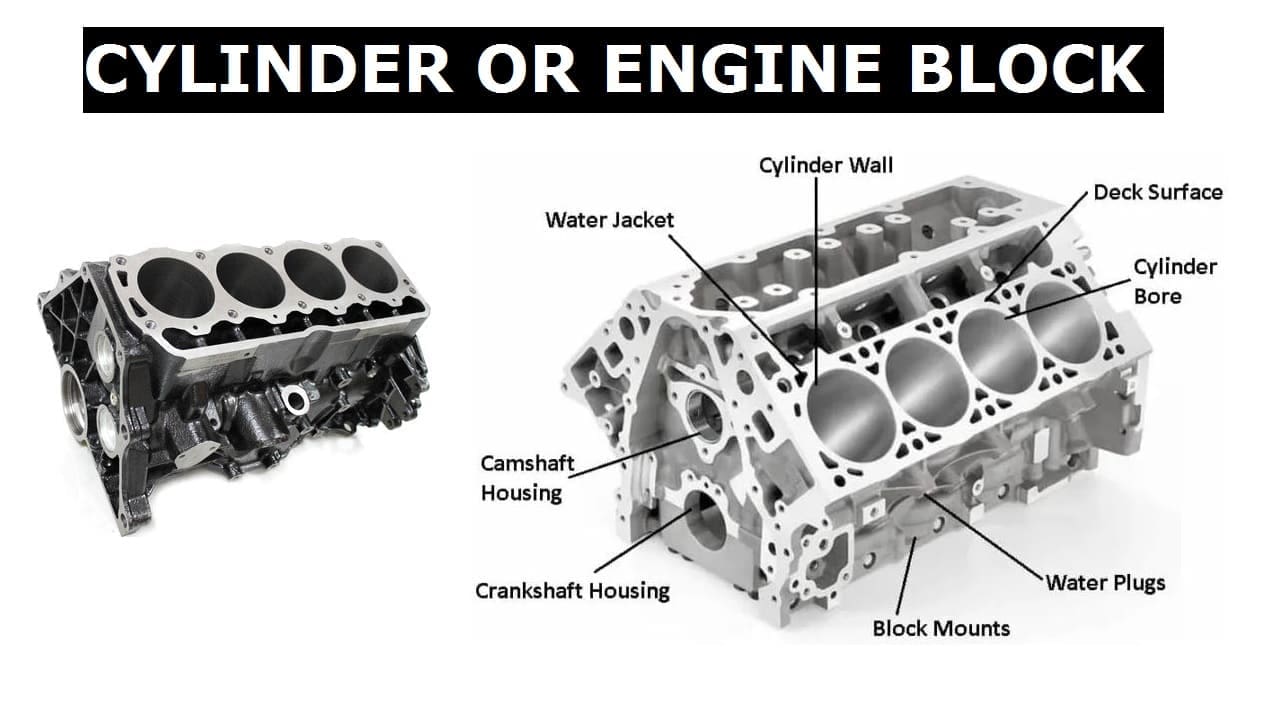

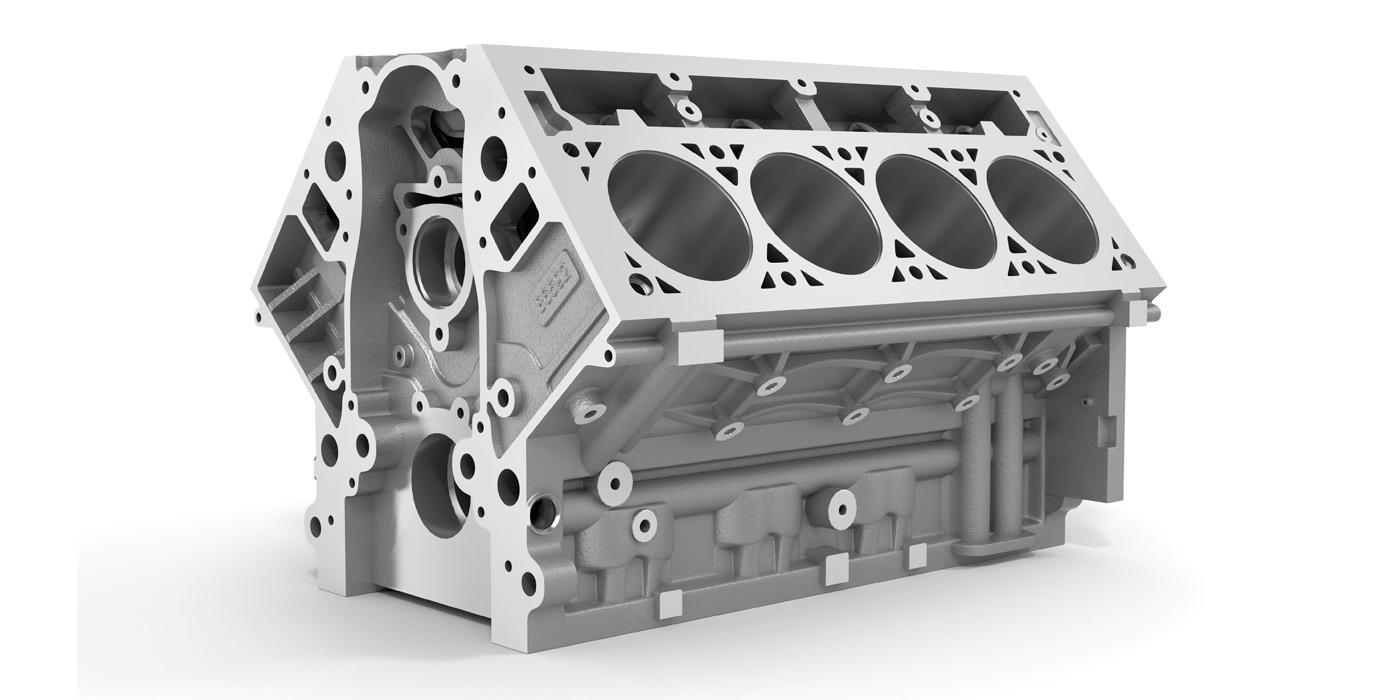

An engine block is a crucial component of an internal combustion engine. It serves as the foundation for the cylinders, pistons, and other moving parts of the engine. The material used to construct the engine block plays a significant role in the overall performance and durability of the engine.

Traditionally, engine blocks have been made of cast iron, a durable and relatively inexpensive material. However, as engine technology has evolved, so too have the materials used to construct engine blocks.

One alternative to cast iron is aluminum. Aluminum engine blocks are lighter in weight than their iron counterparts, which can lead to improved fuel efficiency and performance. They also have a higher heat conductivity, allowing them to dissipate heat more effectively and potentially leading to longer engine life. However, aluminum engine blocks are more expensive to manufacture and are not as durable as cast iron.

Another option is composite materials, such as plastic or fiberglass reinforced plastic (FRP). These materials offer even greater weight savings compared to aluminum, and can also offer improved heat dissipation. However, composite materials are not as widely used in engine blocks due to their relatively low strength and durability compared to metal alloys.

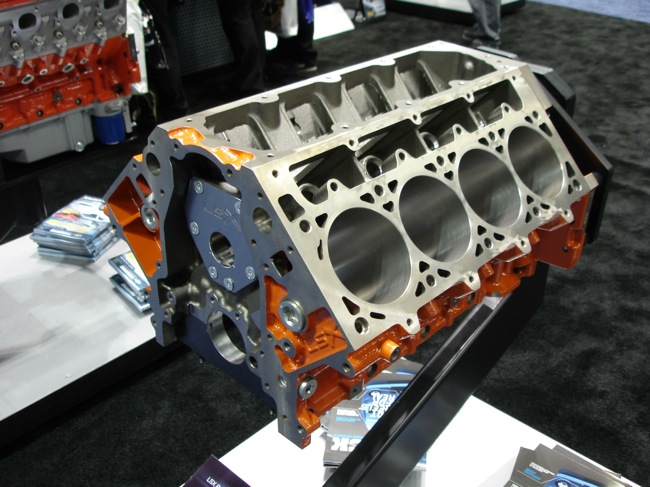

In recent years, there has been increasing interest in using high-strength steel alloys for engine blocks. These alloys offer a good combination of strength, durability, and weight savings compared to traditional cast iron blocks. They also have good heat dissipation properties, making them suitable for use in high-performance engines.

Ultimately, the choice of material for an engine block depends on the specific needs and requirements of the engine. Cast iron remains a popular choice due to its low cost and durability, while aluminum and high-strength steel alloys are used in more specialized applications where weight savings or improved performance are a priority. Composite materials may also be used in certain situations, although they are not as widely adopted as metal alloys.