A marcet boiler is a type of closed-loop, energy-efficient system that is used to heat water or other fluids. It is named after its inventor, French engineer Jean Marcet, who developed the first prototype in the early 19th century.

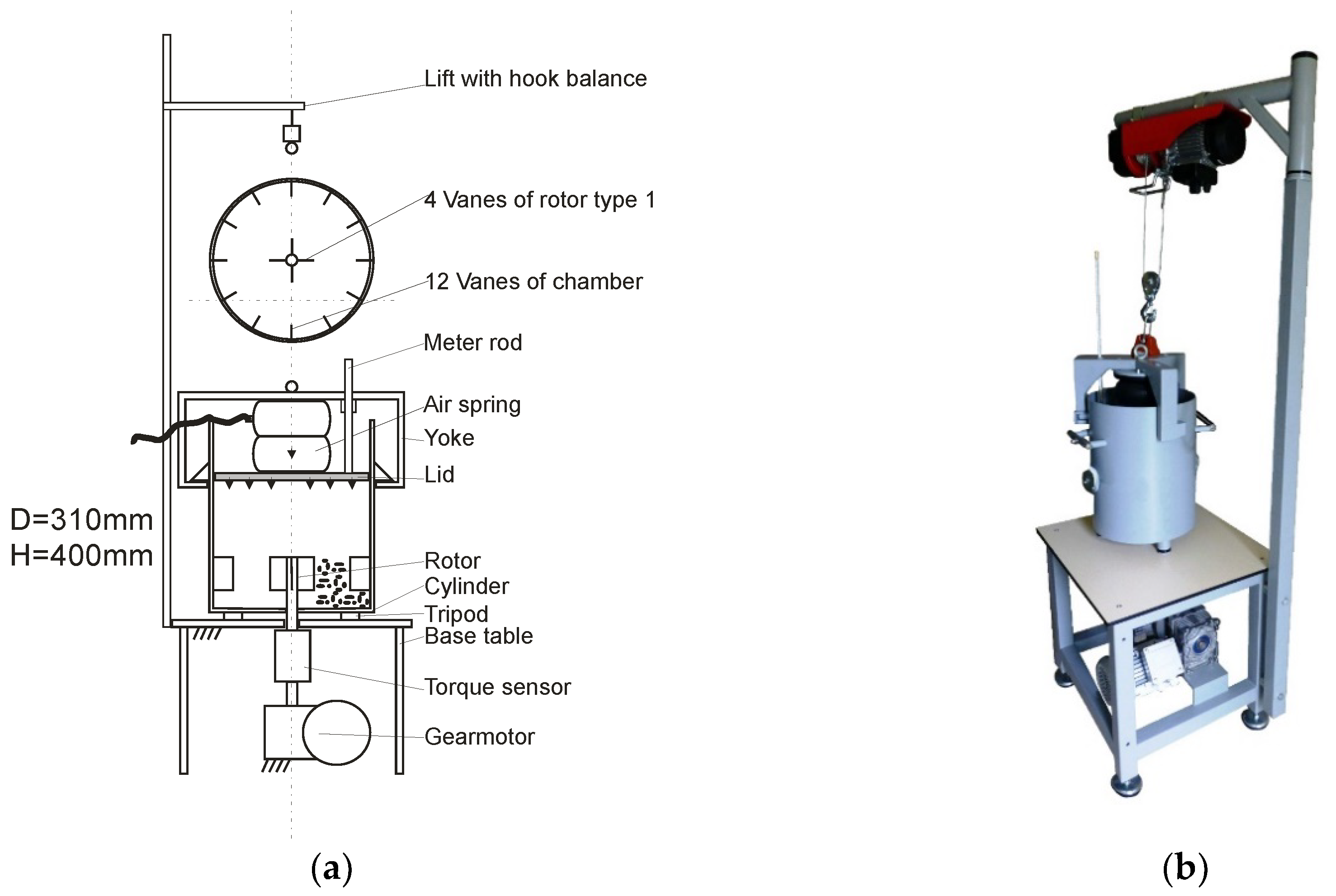

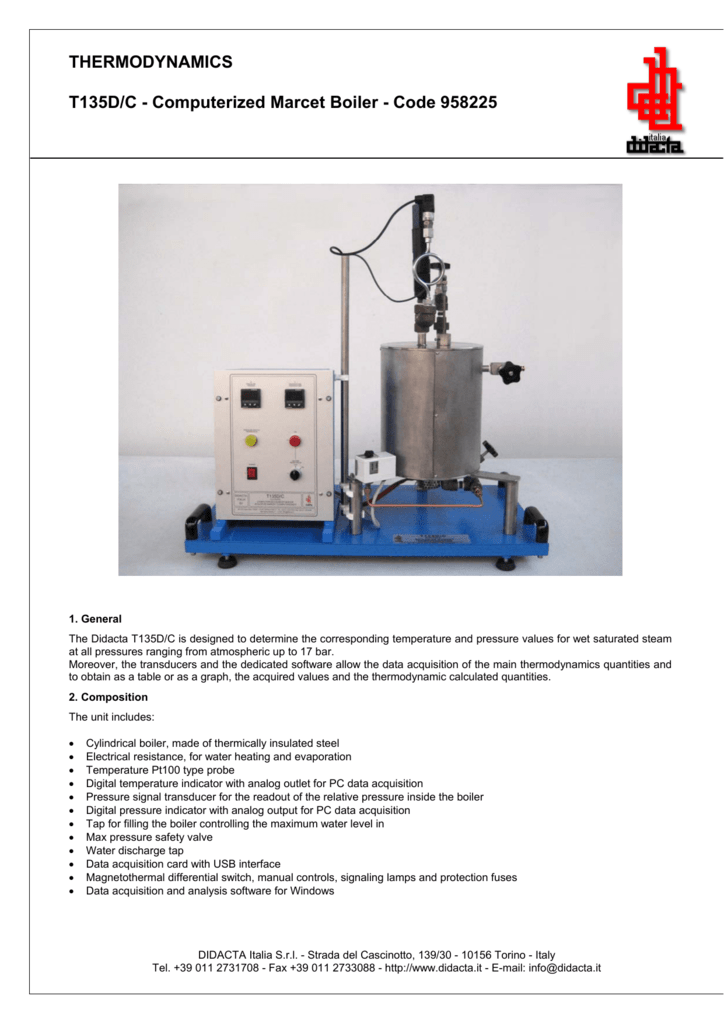

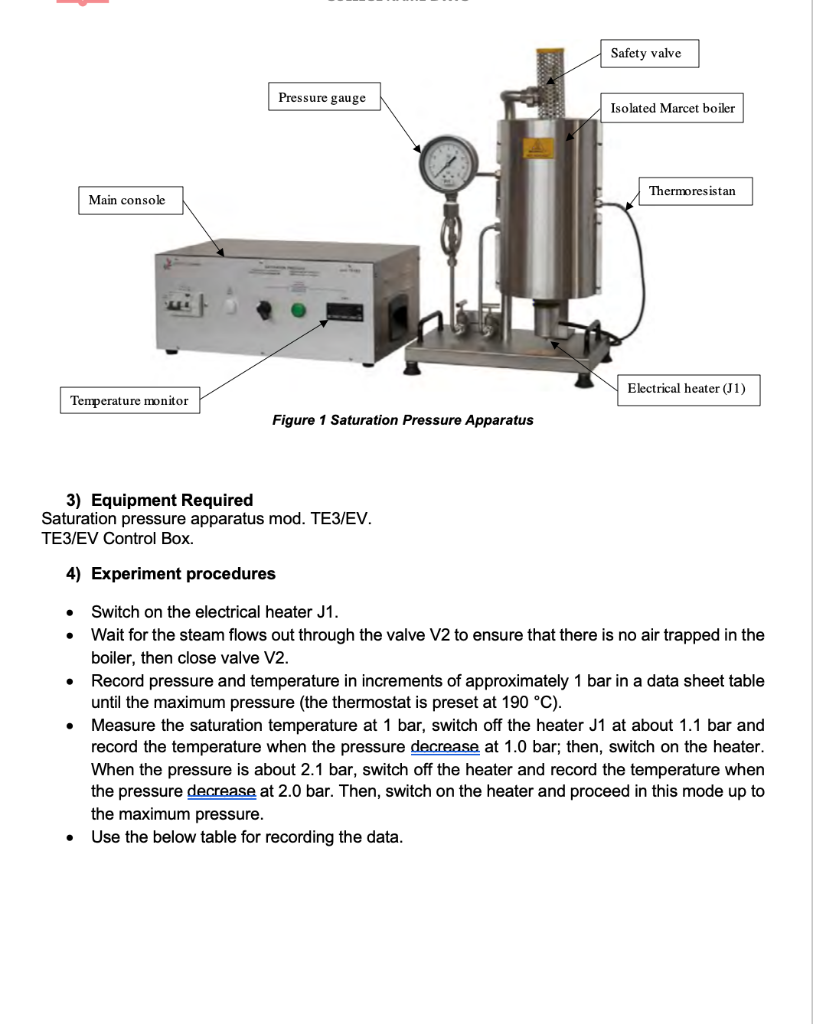

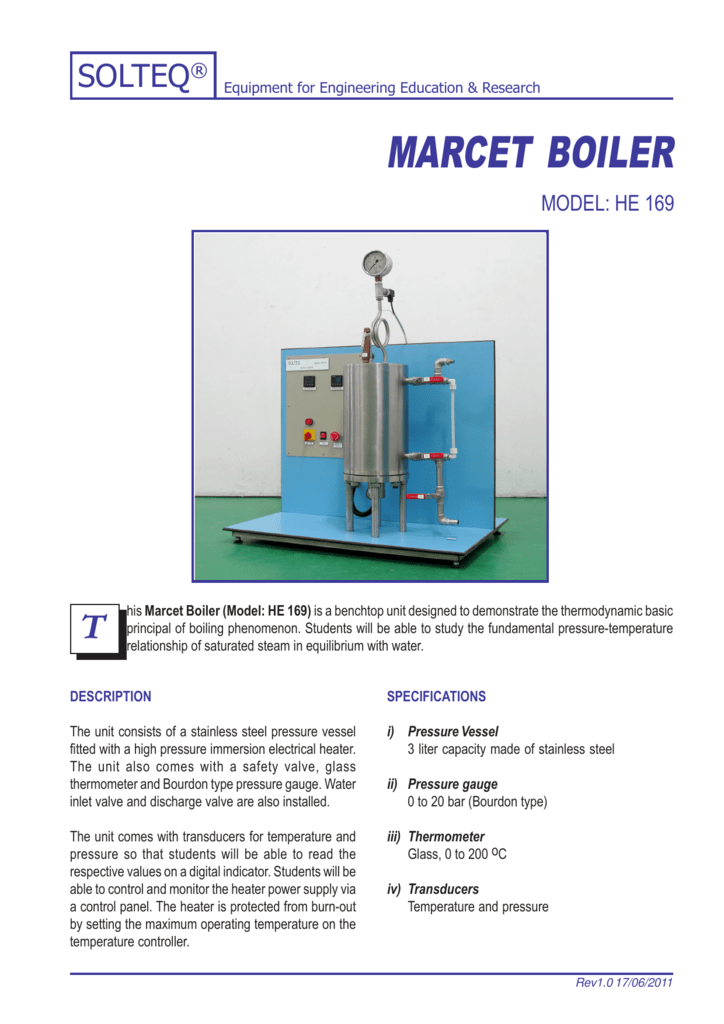

The basic diagram of a marcet boiler consists of a closed vessel or container filled with water, a heat source, and a heat exchanger. The heat source, which is typically a gas burner or electric heating element, is used to heat the water inside the vessel. The heat exchanger, which can be a coil of pipes or a flat surface, transfers the heat from the burner or heating element to the water in the vessel.

As the water is heated, it begins to expand and rise to the top of the vessel. This causes a layer of cooler, denser water to sink to the bottom of the vessel, where it is then heated by the heat exchanger. This process, known as convection, allows the marcet boiler to efficiently transfer heat from the heat source to the water in the vessel.

One of the main advantages of a marcet boiler is its high energy efficiency. Because the system is closed-loop, it does not lose heat to the surrounding environment, which allows it to operate at a higher efficiency than an open-loop system. Additionally, the use of a heat exchanger allows the marcet boiler to transfer heat more efficiently than other types of boilers that rely on direct contact between the heat source and the water.

Marcet boilers are commonly used in a variety of applications, including residential and commercial hot water systems, industrial processes, and power generation. They are also used in some transportation systems, such as trains and ships, to provide heat and hot water.

Overall, the marcet boiler is a reliable and efficient way to heat water or other fluids. Its closed-loop design and use of a heat exchanger make it a highly efficient system, and it has a wide range of applications in both residential and industrial settings.