Material for engine block. Engine Block Materials [Discover] 2022-12-20

Material for engine block

Rating:

5,8/10

1421

reviews

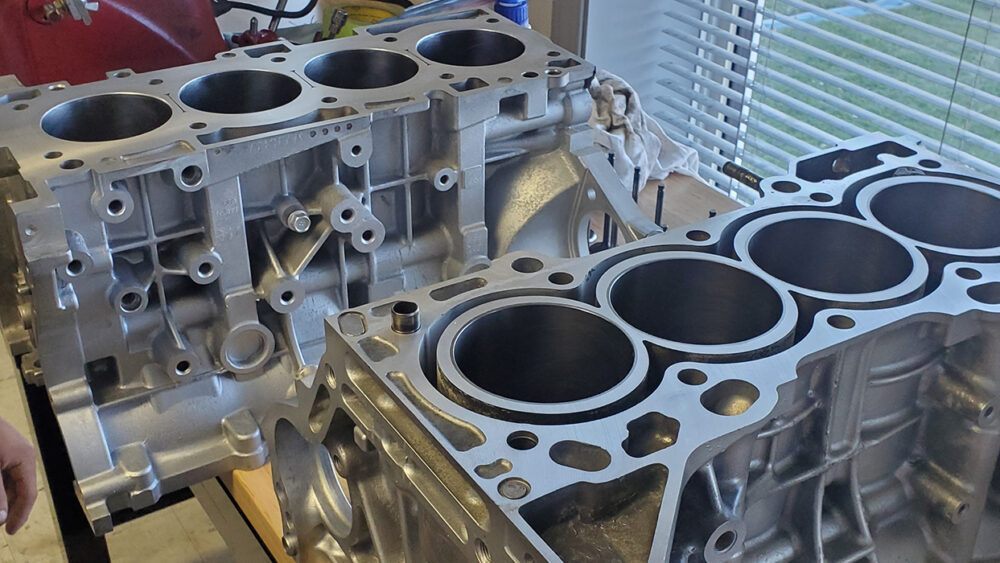

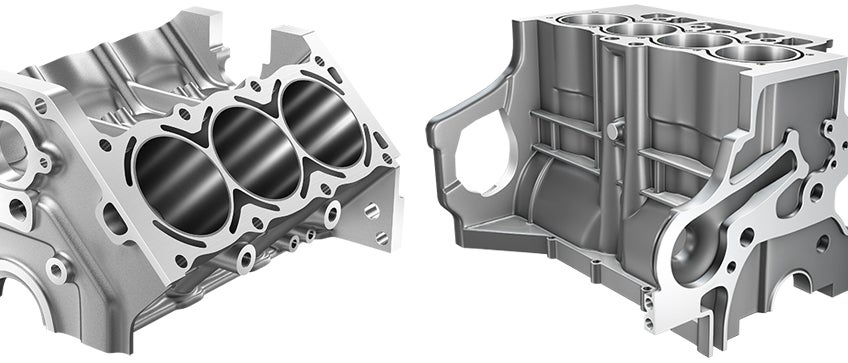

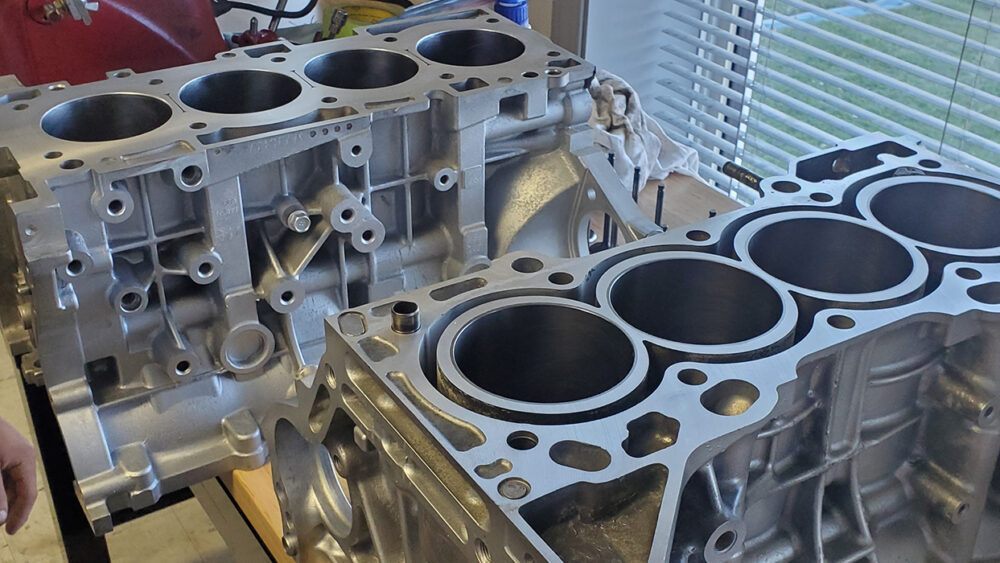

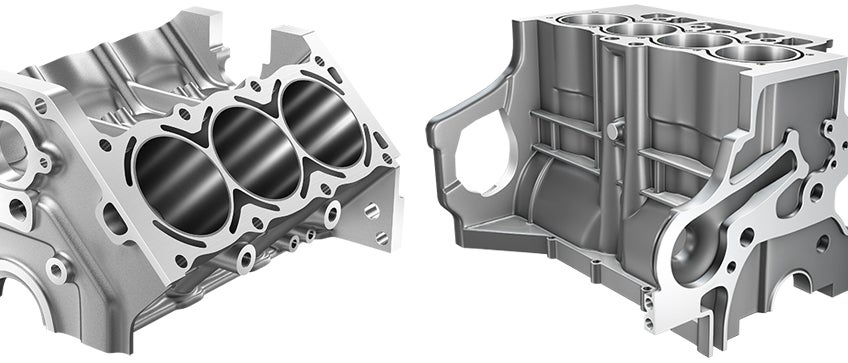

An engine block is the central part of an internal combustion engine, typically made of cast iron or aluminum. The primary function of the engine block is to provide a solid foundation for the various components that make up the engine, such as the cylinders, crankshaft, and pistons. In addition, the engine block is responsible for dissipating heat generated during the combustion process and ensuring that the engine runs smoothly and efficiently.

There are several factors that must be considered when selecting a material for an engine block. One of the most important is the strength and durability of the material. The engine block must be able to withstand the high temperatures and pressures that are generated during the combustion process, as well as the mechanical stresses of the moving parts. In addition, the material must be able to withstand the corrosive effects of the fuel and lubricants that are used in the engine.

Cast iron has long been the traditional material for engine blocks, due to its strength and durability. However, it is also heavy and prone to cracking under extreme conditions. In recent years, aluminum has become a popular alternative due to its lighter weight and better heat dissipation properties. Aluminum engine blocks are also more resistant to corrosion, but they may not be as strong as cast iron and may require additional reinforcing to withstand the stresses of the engine.

Other materials that have been used for engine blocks include steel and composite materials such as plastic and carbon fiber. These materials offer some advantages over traditional materials, such as improved strength and corrosion resistance, but may be more expensive and may not be suitable for all applications.

In conclusion, the material used for an engine block must be strong, durable, and able to withstand the high temperatures and pressures of the combustion process. Cast iron and aluminum are the most common materials used, but other materials such as steel and composite materials may also be used depending on the specific needs of the engine.

Advanced Engine Materials, by EPI Inc.

The aluminum alloy used in BMW engines is a special type called an alloy that is 50% aluminum and 50% nickel. This alloy Elektron-675 represents a step-change upward in mechanical properties. Camshaft Housing We mount the camshaft also in the engine block. So, it is imperative for the aluminium alloys to undergo the heat treatment. They are referred to as "wet liners" because their outer sides come in direct contact with the engine's coolant.

Next

What Are BMW Engine Blocks Made Of?

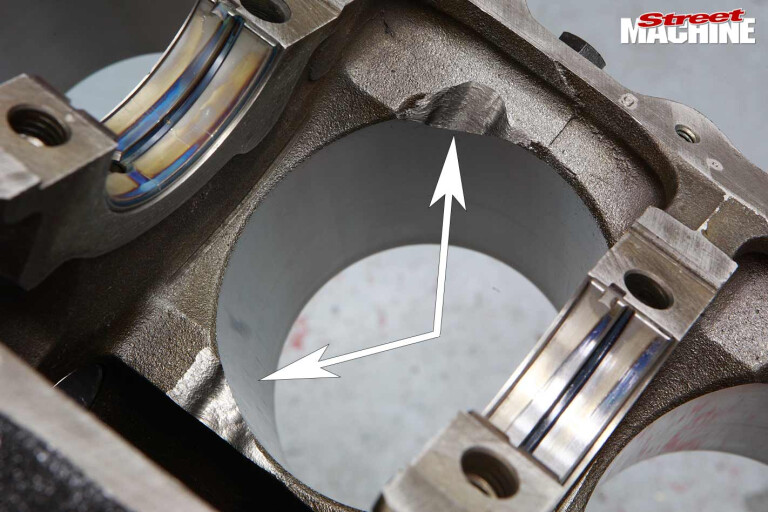

Comparison Table Here is a comparison table highlighting the differences between a Cast Iron engine block and an Aluminium engine block. I was told by Allegheny Technologies Ltd. The density of these materials is as below. Porous engine block Voules in the casting are frequently not noticed for a very long time because they were brought on by impurities that entered the metal during the manufacturing process. These blocks are designed to offer the best of both worlds in terms of weight and heat dissipation. Crankshaft Housing Also, the crankshaft is a very important part that is responsible for the production of the rotational motion. The casted block is then machined to achieve the required dimensions and smooth out the surfaces.

Next

What Is Engine Block?

HRc is the most frequently used scale for steels; HRb is a common measurement for softer metals. Some manufacturers make DLC-coated intake valves and spring retainers from 6AL-4V, but this manufacturer makes both its intake and exhaust valves from its proprietary version of Ti-6242. This alloy has good casting features, corrosion resistance, and good thermal conductivity. Also, the smaller ones are the attachment bores for the engine head. Aluminium engine blocks also help in reducing the emissions. For instance, having enough ventilation in the mold will help you avoid blowholes, whereas using sand with small grains will help you avoid metal penetration.

Next

How Engine Block Is Made (All You Need To Know)

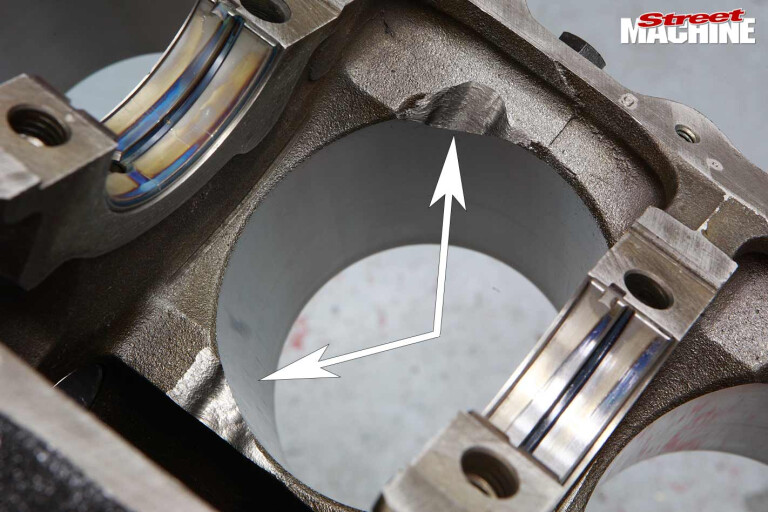

Therefore, these alloys are subjected to receive a Without the heat treatment, these alloys will be too weak and unsuitable for the engine blocks. It is responsible for transferring the power from the engine to the wheels. Aluminum blocks handle heat better than iron blocks. Blowholes in the casting often do not cause any problems at all for a long time. I was told that it is typically quite difficult to investment-cast magnesium alloys to obtain thin-wall therefore very lightweight parts.

Next

Materials Used for the Engine Block

We stated that the general construction of the engine cylinders and connecting rods are very important. A car engine block, commonly known as a cylinder block, acts as a structural framework or housing for all the essential components required for combustion. A356 aluminum alloy contains 91. Common Problems With Engine Blocks The engine block is built to last for the entire life of the vehicle because it is a sizable, precisely machined piece of metal. But, an aluminum block tends to suffer more than an iron block, especially at lower thresholds. The nickel also helps to reduce friction, which results in a longer engine life.

Next

Engine Block Repair Material

The biggest ones are the cylinder holes. Ease of Rebuilding Iron engine blocks are typically easier and cheaper to rebuild. Also, some automotive brands are using this technology such as The most important disadvantage of this technology, the repair times are very long. Do local mechanics know how to repair. Computerized milling machines and boring machines are used in this operation How An Engine Block Is Made Sand casting is the method that produces engine blocks the most frequently and widely.

Next

Engine Block Materials [Discover]

. So, crankcases are part of the engine blocks in boxer types. We can remove the cylinder liners with new ones. The company has been using this material for over 100 years and it is still the best choice for engine blocks. . The most common materials are aluminum and cast iron.

Next

Guide to Engine Block Making: Process, Materials & More

While BMW has completely moved out of the practice, they still use cast iron liners in certain engines. But ring packages, ring materials, and the technology used to finish the cylinders has come a long way over the years. With the liners, we prevent corrosion and damage to the engine block and hole. So, the total of these systems creates the general cylinder construction. Inside the engine block, where the combustion process takes place, high pressure and temperature environment must be maintained. To elaborate, the engine block is the main housing, which accommodates all the essential components including pistons, cylinder heads, camshafts, valves, crankshafts, oil galleries and coolant passages in modern engines.

Next

Make The Case: Iron vs. Aluminum Engine BlocksPerformance Racing Industry

The purpose of the engine block is to support the components of the engine. The tensile strength of these iron classes ranges between 20,000 to 25,000 psi. Imagine the possibilities for a fully-titanium monocoque chassis…… Making titanium valves survive in the harsh operating environment of a Formula One or Cup engine was a substantial challenge, especially in the case of exhaust valves, which are exposed to extremes of temperature and corrosive gasses along with high levels of fatigue loading zero-max-zero plus bending , with quasi-impact compressive loads on the tip and seat. Having said that, any leaks that may arise from a porous block should be minor. You can see the places of core plugs at the sides of engine blocks. The chemistry, thus the alloying system, is presently undisclosed while the patent is being sought.

Next

Materials Used for the Engine Block Free Essay Example 538 words

Around these technologies, you can find; integrated crankcases, integrated cylinder heads, and integrated transmission. Furthermore, it is very important to know the general breakdowns and failures of the engine blocks. The surface of the block will wet and you can inspect if it is a coolant liquid or oil. That being said, iron blocks are not completely out of usage because the GM LS Series and Ford's Modular engines still use cast iron blocks. It is interesting to note that the nomenclature "6Al-4V" has become nearly a generic, because there are more than 20 different variations available, all having the same basic chemistry but with differing melt practices, impurity tolerances, inspection requirements, etc.

Next