Raw material identification through color coding is a common practice in manufacturing and production settings. It involves the use of different colors to distinguish between different types of raw materials, helping to ensure that the correct materials are used at each stage of the production process.

There are several benefits to using color coding for raw material identification. One of the main benefits is improved efficiency. When raw materials are clearly marked with different colors, it becomes much easier for workers to quickly and accurately identify the materials they need. This can save time and reduce the risk of errors, which can result in increased productivity and reduced costs.

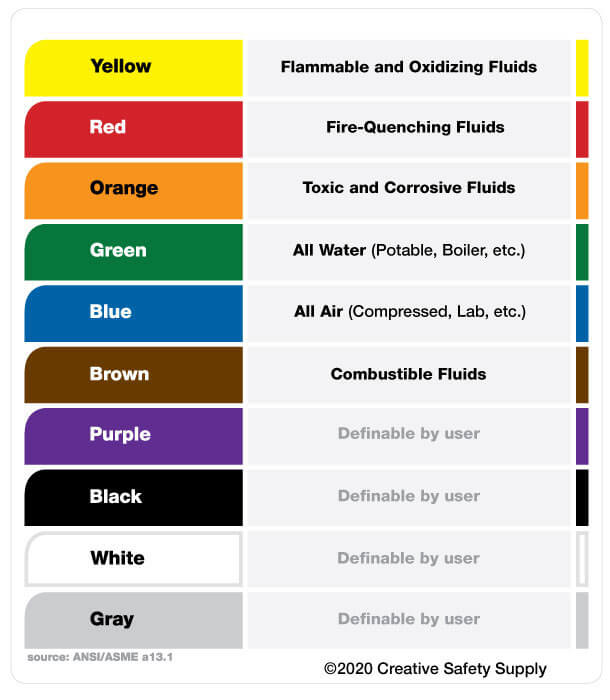

Another benefit of color coding is improved safety. Some raw materials may be hazardous or toxic, and it is important to ensure that they are handled properly. By using color coding, it is easier for workers to identify these materials and take the necessary precautions to protect themselves and others.

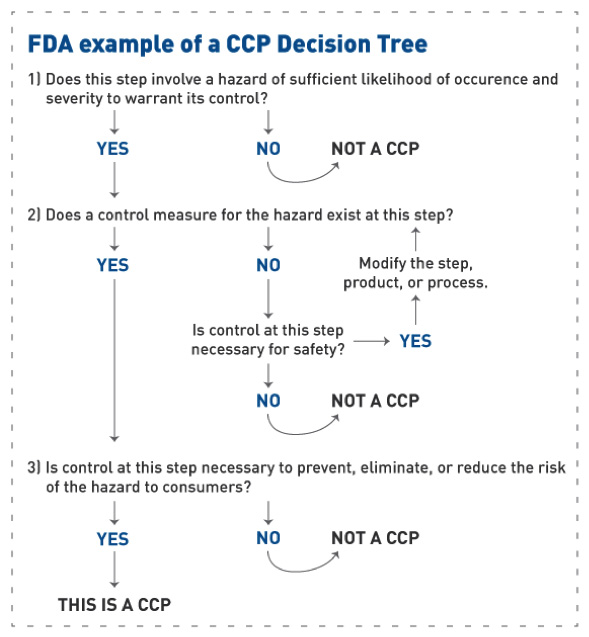

Color coding can also help to improve quality control. When different raw materials are clearly marked with different colors, it becomes easier for workers to identify any materials that may be defective or out of specification. This can help to reduce the risk of using faulty materials in the production process, which can result in improved product quality.

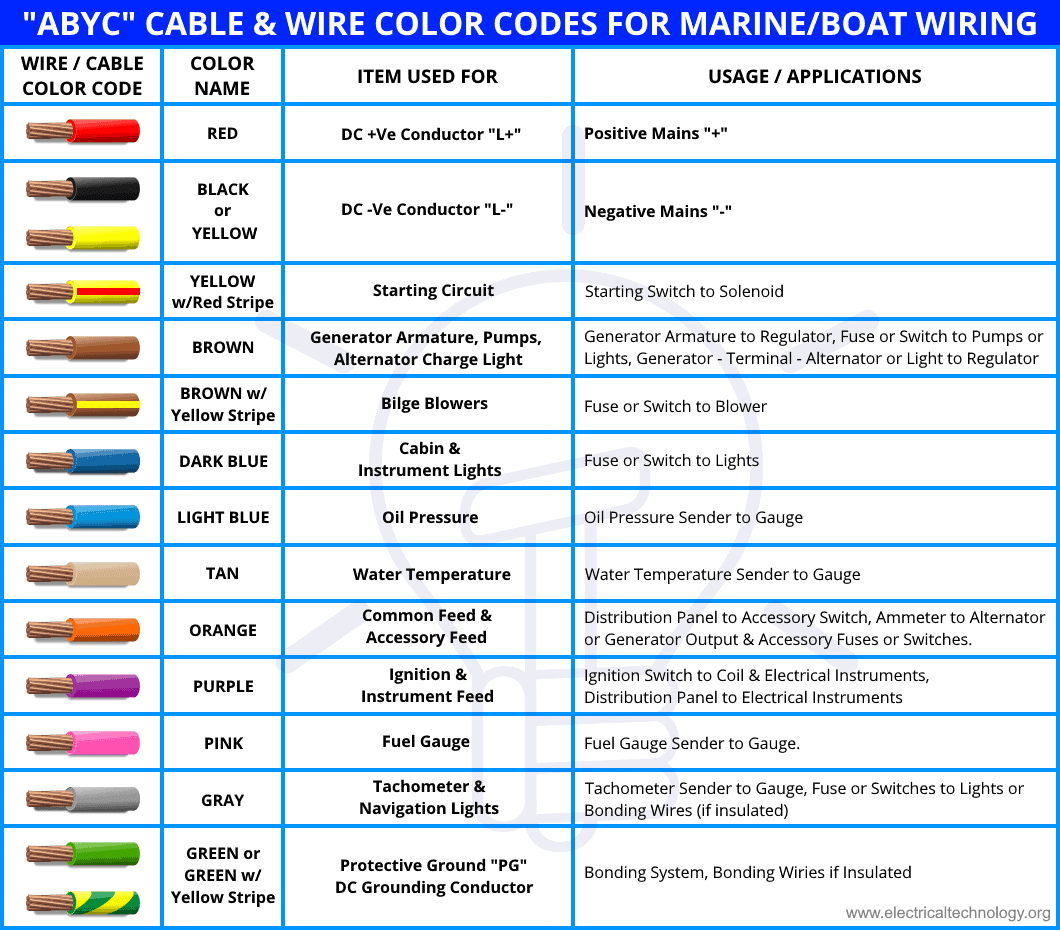

There are a few different approaches to implementing color coding for raw material identification. One approach is to assign a specific color to each type of raw material. For example, one color may be used to identify steel, another color may be used to identify plastic, and so on. Another approach is to use different shades or hues of the same color to differentiate between different grades or types of a particular raw material.

Regardless of the approach used, it is important to establish clear guidelines and procedures for using color coding in the production process. This may include training workers on how to correctly identify and use the different colors, as well as setting up a system for tracking and managing the colors used.

In conclusion, raw material identification through color coding is a useful tool for improving efficiency, safety, and quality control in manufacturing and production settings. By clearly marking different types of raw materials with different colors, it becomes easier for workers to identify and use the correct materials, resulting in increased productivity and reduced costs.