Rice milling is an important industry in India, as rice is a staple food for a majority of the population. The rice milling industry in India has grown significantly, with the increase in demand for rice and the advancement of technology in rice milling.

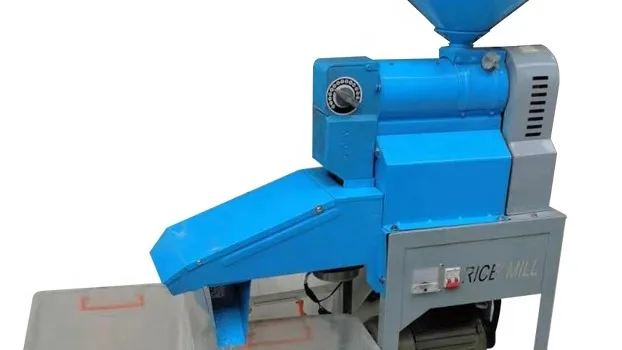

In India, rice milling is typically carried out by small and medium-sized enterprises, with a few large-scale companies also operating in the sector. Rice mills in India can be classified into two categories: huller mills and modern mills. Huller mills are traditional rice mills that primarily remove the outer husk of the rice grain, while modern mills are equipped with machines that can remove the husk and polish the grain.

The rice milling industry in India has undergone significant changes in recent years, with the introduction of modern technology and machinery. This has led to an increase in efficiency and productivity, as well as a reduction in the time and labor required for rice milling. Rice mills in India are now able to process large quantities of rice in a shorter period of time, leading to increased profits for mill owners.

One of the major challenges faced by the rice milling industry in India is the lack of access to finance. Many small and medium-sized rice mills struggle to secure loans from banks and financial institutions, which can limit their ability to invest in modern machinery and technology. Another challenge is the lack of quality control in the sector, which can result in the production of low-quality rice that may not meet the standards of consumers.

Despite these challenges, the rice milling industry in India has great potential for growth. With the increasing demand for rice, and the adoption of modern technology and machinery, the industry is well positioned to meet the needs of the country's growing population. To ensure the long-term viability of the industry, it is important that the government and private sector invest in the development of the sector, including the provision of access to finance and the implementation of quality control measures.

In conclusion, the rice milling industry in India plays a vital role in the country's economy, as it is a major source of employment and a key contributor to the production of a staple food. While the industry faces challenges, it has the potential to grow and thrive with the adoption of modern technology and the support of the government and private sector.

Rice Mill Industry in India

Galore Impex This firm has been operational since 2015, and it is now functioning as a merchant exporter, in addition to operating as a supplier. The following documents must be provided along with the application. Of course, in any kind of business feasibility study or the planning stage is always the first step to take. Committed to complete consumer satisfaction our company is an ISO 22000:2005, HACCP and GMP approved company. Our product line is broadly praised by customers for rich flavor, alluring aroma, and refreshing taste. It is the place for buyers to procure Agri Commodities online at the best competitive prices. The rice milling industries uses mechanical devices to process paddy.

How to Start a Rice Business in India

Grainville acts as procurement agents for buyers from around 135 countries on over 288 sea ports- allocating their business to thousands of competent sellers registered with us, helping them fulfil the same in the most efficient way possible and quality assure the shipment as per specification chosen by buyers while placing order on the platform. If the promoters have the capital necessary for the business, our expert consultants will take care of all the licensing, paperwork and machine installation for initiating your operations. Once the paddy grains are harvested, they are analyzed by the Quality Experts, who then hand pick the Best grains. The result has been equally rewarding-having the largest installed capacity in the industry with quality certifications to ensure satisfaction to both the buyers and the eventual consumers. Stones and dust are removed from paddy and put into de-husker which gives brown rice. The packed rice is then stored in our godowns, from where the deliveries are made to the customers. These are just the basic necessities of this kind of rice business for you to be able to start and eventually and hopefully sell after the harvest season.

Gaganricemills

We are fully automated rice processing company with state of the art machinery to guarantee great quality and adhering to the business concept of qualitative service delivery. A remarkable market capitalization of 6 billion Indian Rupees is achieved by the firm as a direct result of the unwavering dedication to improving both product quality and the level of service provided to customers. Rice is obtained from paddy, a mixture of husk, bran and rice grain. Improved paddy seeds, rice whitening machines, increased investment, technology up gradation, modernization, and government supportive policies and schemes are the growth drivers of the Rice Milling Industry. There may be an pressing have to encourage public-private partnership in constructing such services and making certain their correct upkeep. How Can Vakilsearch Assist You? Ask yourself what kind of rice business you want: rice farming business, rice dealership business, rice mill business, and wholesale or retail rice selling business. The company continues to engage its customers and other stakeholders to ensure an adequate supply of our product nationwide.