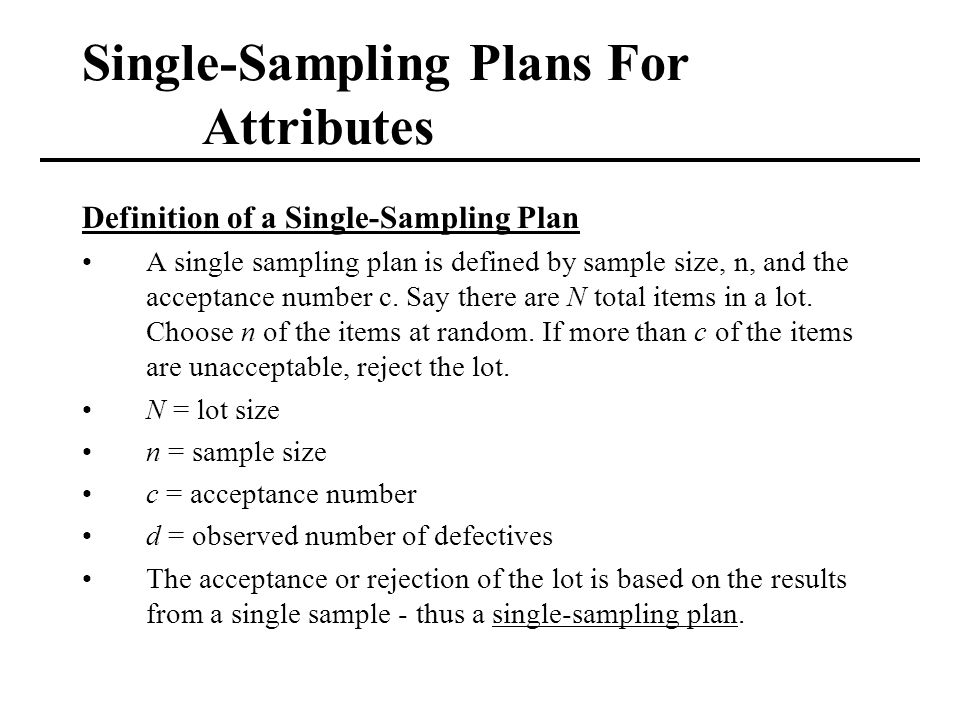

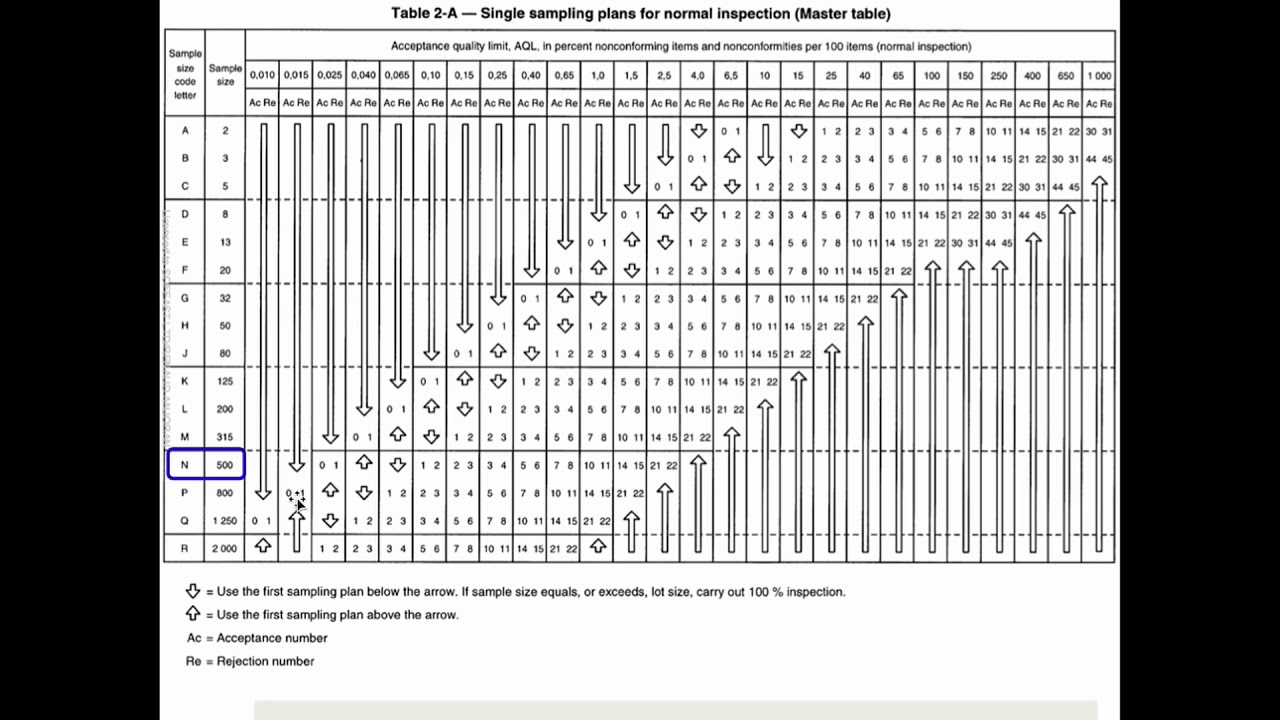

A single sampling plan is a statistical method used to inspect a batch of goods or materials to determine whether it meets certain quality standards. This method involves taking a sample of items from the batch and testing them to see if they meet the required specifications. If the sample meets the specifications, the entire batch is considered acceptable. If the sample does not meet the specifications, the batch is considered defective and is either rejected or subjected to further testing.

Single sampling plans are commonly used in industries such as manufacturing, food processing, and pharmaceuticals, where it is important to ensure that the goods being produced meet certain quality standards. These standards may be set by the manufacturer, the customer, or regulatory agencies.

One advantage of using a single sampling plan is that it is a cost-effective way to test large batches of goods. It is much more efficient to test a small sample of items rather than testing every single item in the batch. This can save time and resources, especially if the batch is large.

Another advantage is that single sampling plans can be designed to be highly accurate. By carefully selecting the sample size and the test criteria, it is possible to achieve a high level of confidence in the results of the inspection. This can help to ensure that only high-quality goods are produced and sold to customers.

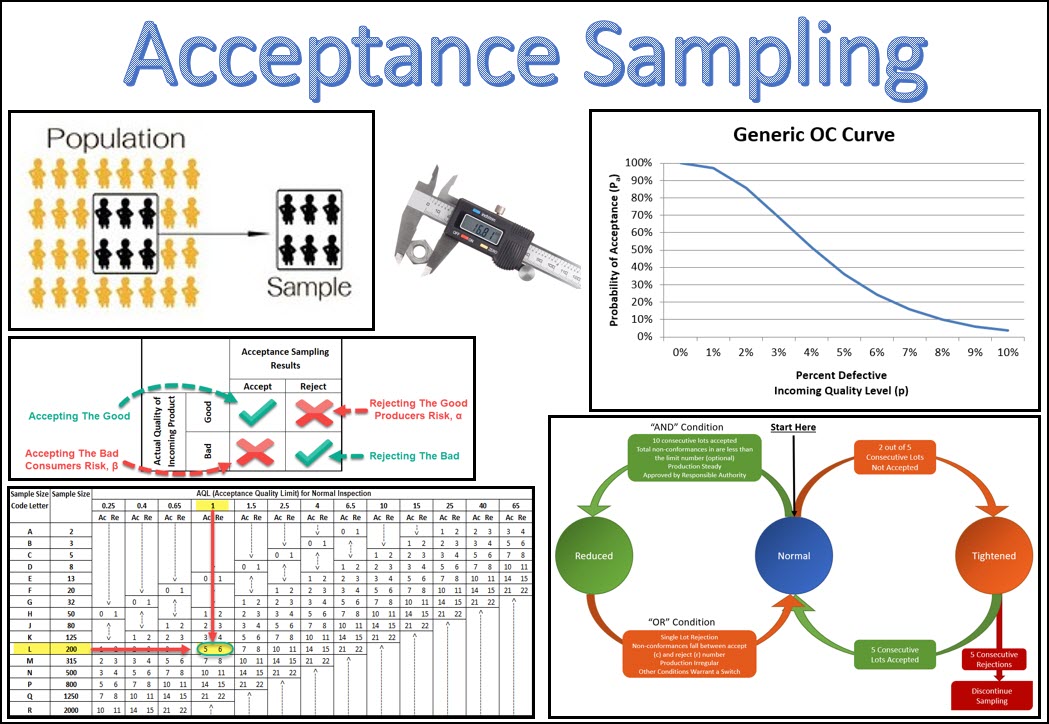

However, there are also some limitations to single sampling plans. One potential issue is that they rely on statistical assumptions, which may not always hold true. For example, if the sample is not representative of the entire batch, the results of the inspection may not accurately reflect the quality of the batch as a whole. This can lead to false positives (i.e., a batch is rejected even though it meets the specifications) or false negatives (i.e., a batch is accepted even though it does not meet the specifications).

Another limitation is that single sampling plans may not be suitable for all types of goods. In some cases, it may be necessary to test every single item in the batch to ensure that it meets the required quality standards. This is especially true for goods that have a high risk of failure, such as medical devices or aircraft parts.

In conclusion, single sampling plans are a useful tool for inspecting batches of goods to ensure that they meet certain quality standards. While they have some limitations, they can be an efficient and accurate way to test large batches of goods, especially in industries where it is important to ensure that the goods being produced are of high quality.