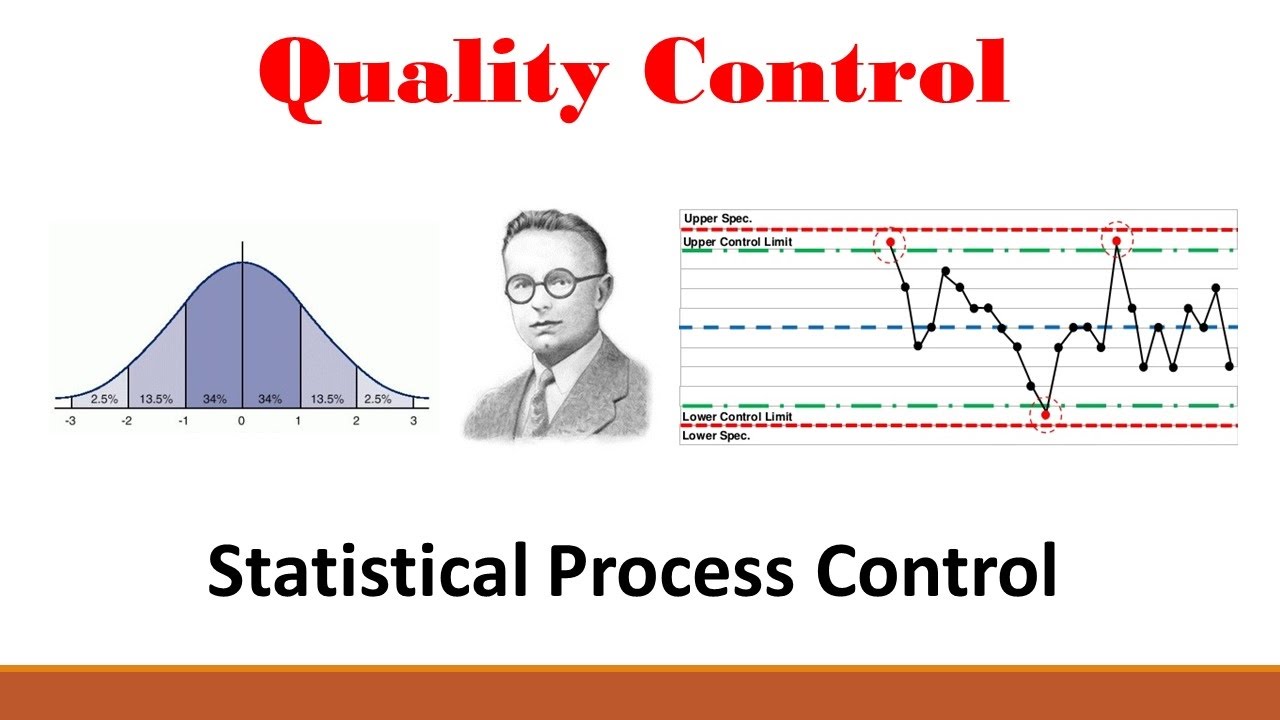

Statistical quality control charts are graphical tools used to monitor and control a process in order to ensure that it is operating within predetermined limits. These charts are used in a variety of industries, including manufacturing, healthcare, and service industries, to monitor processes such as the production of goods, patient outcomes, and customer satisfaction.

The main purpose of a quality control chart is to detect changes in the process that may impact the quality of the product or service being produced. For example, if a manufacturing process is producing goods with an unacceptable level of defects, a quality control chart can be used to identify the source of the problem and make necessary adjustments to the process in order to bring it back within acceptable limits.

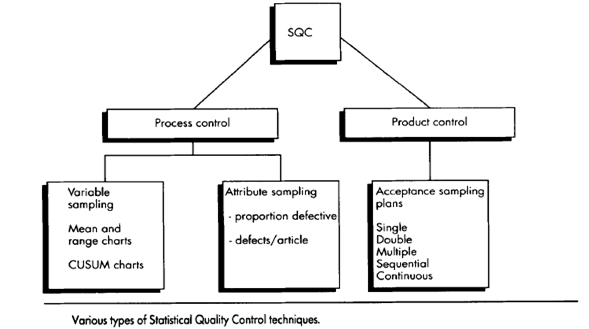

There are several different types of quality control charts that can be used, depending on the type of data being collected and the nature of the process being monitored. The most common types of quality control charts include:

X-bar and R charts: These charts are used to monitor the mean and range of a continuous process over time. The X-bar chart is used to monitor the mean of the process, while the R chart is used to monitor the range.

P chart: This chart is used to monitor the proportion of defective items in a process.

C chart: This chart is used to monitor the number of defects in a process.

NP chart: This chart is used to monitor the number of nonconforming items in a process.

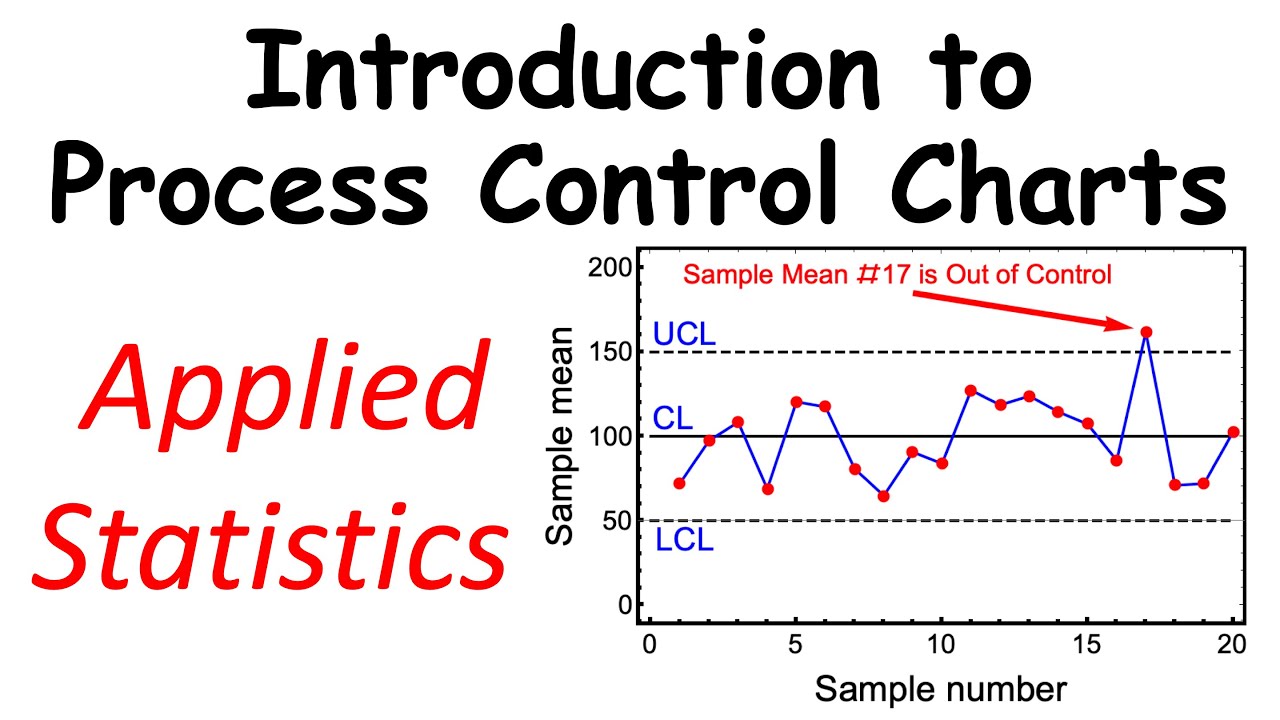

In order to use a quality control chart effectively, it is important to establish control limits for the chart. These limits are based on statistical calculations and represent the expected range of variation for the process being monitored. If the data collected falls outside of these limits, it may indicate that there is a problem with the process that needs to be addressed.

There are many benefits to using quality control charts in a business or organization. They can help identify problems with a process early on, allowing for quick corrective action to be taken. This can help reduce the number of defects and improve the overall quality of the product or service being produced. Quality control charts can also help improve efficiency by identifying areas of the process that may be causing unnecessary waste or inefficiency.

In conclusion, statistical quality control charts are a valuable tool for monitoring and controlling processes in order to ensure that they are operating within predetermined limits. They can help improve the quality of products and services, reduce defects, and increase efficiency, making them an important part of any quality control program.