Quality management is a field that has evolved significantly over the past several decades. It is a discipline that focuses on ensuring that products and services meet or exceed customer expectations and requirements. In this essay, we will examine the evolution of quality management, highlighting key developments and milestones that have shaped the field.

One of the earliest pioneers of quality management was W. Edwards Deming, a statistician and management consultant who worked extensively in post-World War II Japan. Deming developed a set of principles for improving quality and productivity, known as the Deming Cycle or PDCA (Plan-Do-Check-Act). These principles emphasized the importance of continuous improvement and the need to involve all employees in the quality process. Deming's work was instrumental in Japan's rapid economic growth following the war and his ideas have had a lasting impact on the field of quality management.

Another important figure in the history of quality management is Joseph M. Juran, who developed the concept of "fitness for use" as a key measure of quality. This means that a product or service should be designed and produced in such a way as to meet the needs and expectations of the customer. Juran also emphasized the importance of customer satisfaction and the need to involve all levels of an organization in the quality process.

In the 1980s, the focus of quality management shifted towards the concept of total quality management (TQM). TQM is a holistic approach to quality that seeks to involve all employees in the quest for continuous improvement and customer satisfaction. TQM includes a number of key principles, such as customer focus, continuous improvement, teamwork, and leadership.

In the 1990s, a new quality management model called Six Sigma was developed. Six Sigma is a data-driven approach to quality that aims to identify and eliminate defects in processes and products. It involves the use of statistical tools and techniques to identify and solve problems, with the goal of reducing defects to a level of 3.4 defects per million opportunities. Six Sigma has been adopted by many organizations around the world and has been credited with significant improvements in quality and productivity.

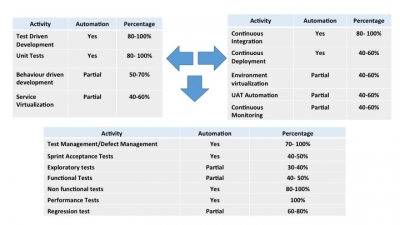

In the 21st century, the focus of quality management has continued to evolve. One key development has been the adoption of the ISO 9001 quality management standard, which provides a framework for organizations to follow in order to ensure that they meet the needs of their customers and other stakeholders. Another important trend has been the rise of agile methodologies in software development, which prioritize flexibility and adaptability over strict processes and procedures.

Overall, the evolution of quality management has been driven by a desire to improve products and services and to meet the changing needs and expectations of customers. From the work of Deming and Juran to the adoption of TQM, Six Sigma, and ISO 9001, the field has undergone significant changes and will undoubtedly continue to evolve in the future.