Friction loss along a pipe is a phenomenon that occurs when a fluid, such as water or gas, flows through a pipe and encounters resistance due to the roughness of the pipe wall and the viscous nature of the fluid. This resistance causes the fluid to slow down and lose energy, resulting in a reduction in pressure and a corresponding decrease in the flow rate of the fluid. Understanding friction loss along a pipe is important in many applications, including the design of piping systems for the transportation of fluids and the calculation of pressure drop in fluid flow systems.

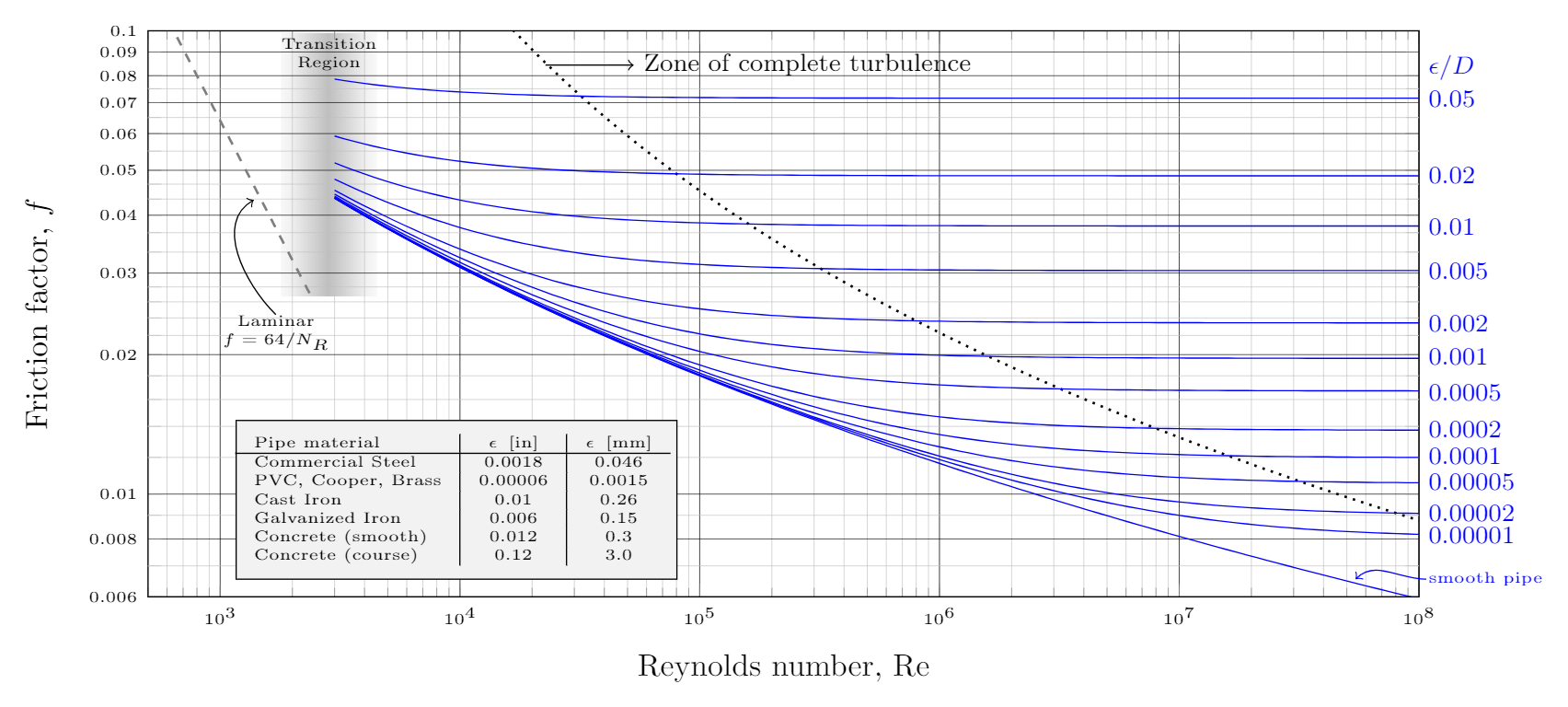

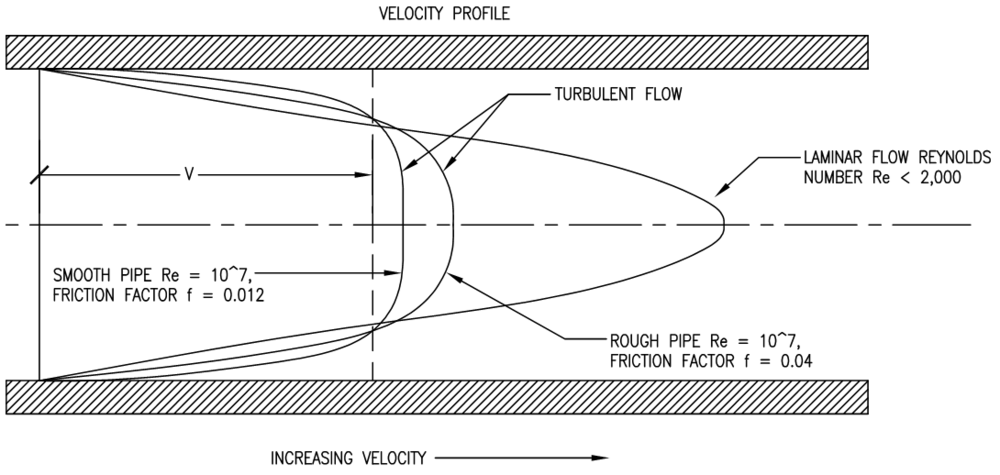

There are several factors that can influence the amount of friction loss along a pipe. One of the most important factors is the roughness of the pipe wall, which can vary significantly depending on the material and surface finish of the pipe. For example, a pipe with a smooth, polished surface will have less friction loss than a pipe with a rough, corroded surface. The diameter of the pipe also plays a role in friction loss, with smaller diameter pipes generally experiencing higher levels of friction loss than larger diameter pipes due to the increased surface area of the pipe wall that the fluid comes into contact with.

The viscosity of the fluid is another factor that can affect friction loss along a pipe. Viscosity is a measure of the resistance of a fluid to flow, and fluids with higher viscosities will generally experience more friction loss than fluids with lower viscosities. For example, water, which has a relatively low viscosity, will experience less friction loss than oil, which has a much higher viscosity. The temperature of the fluid can also affect viscosity, with warmer fluids typically having lower viscosities and experiencing less friction loss than colder fluids.

The flow rate of the fluid is also an important factor in determining the amount of friction loss along a pipe. In general, higher flow rates will result in higher levels of friction loss, as the fluid is moving more quickly and coming into contact with more of the roughness on the pipe wall. Similarly, the length of the pipe can also affect friction loss, with longer pipes generally experiencing higher levels of friction loss due to the increased distance that the fluid must travel and the corresponding increase in the number of opportunities for the fluid to encounter resistance.

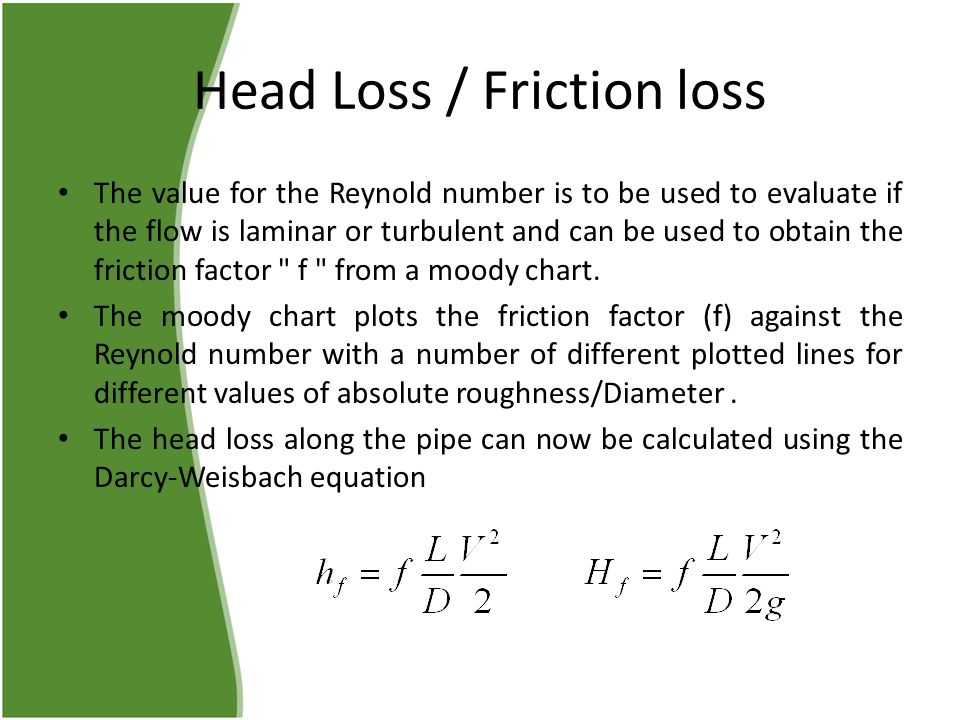

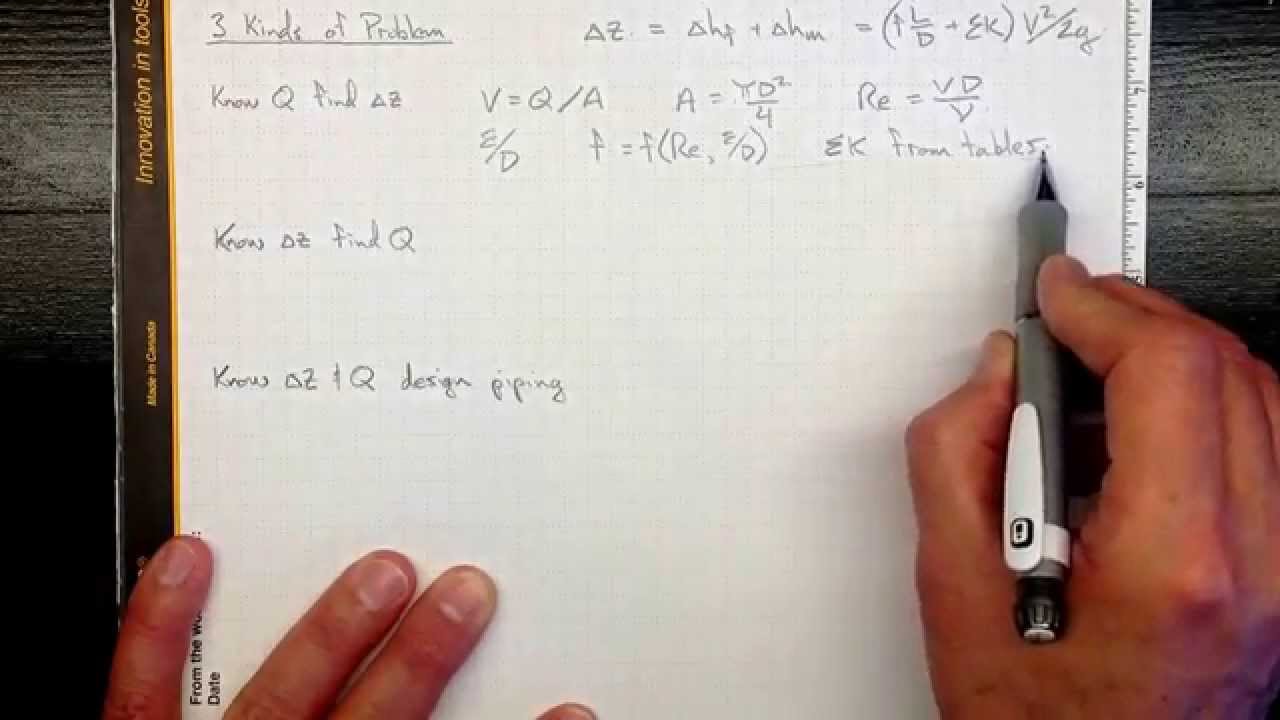

There are several methods that can be used to calculate the amount of friction loss along a pipe, including the Darcy-Weisbach equation and the Hazen-Williams equation. These equations take into account factors such as the roughness of the pipe wall, the viscosity of the fluid, the flow rate, and the diameter of the pipe to determine the pressure drop that will occur along the length of the pipe.

In conclusion, friction loss along a pipe is a phenomenon that occurs when a fluid flows through a pipe and encounters resistance due to the roughness of the pipe wall and the viscous nature of the fluid. Understanding friction loss is important in the design of piping systems and the calculation of pressure drop in fluid flow systems, and several factors, including the roughness of the pipe wall, the viscosity of the fluid, the flow rate, and the length of the pipe, can influence the amount of friction loss that occurs.