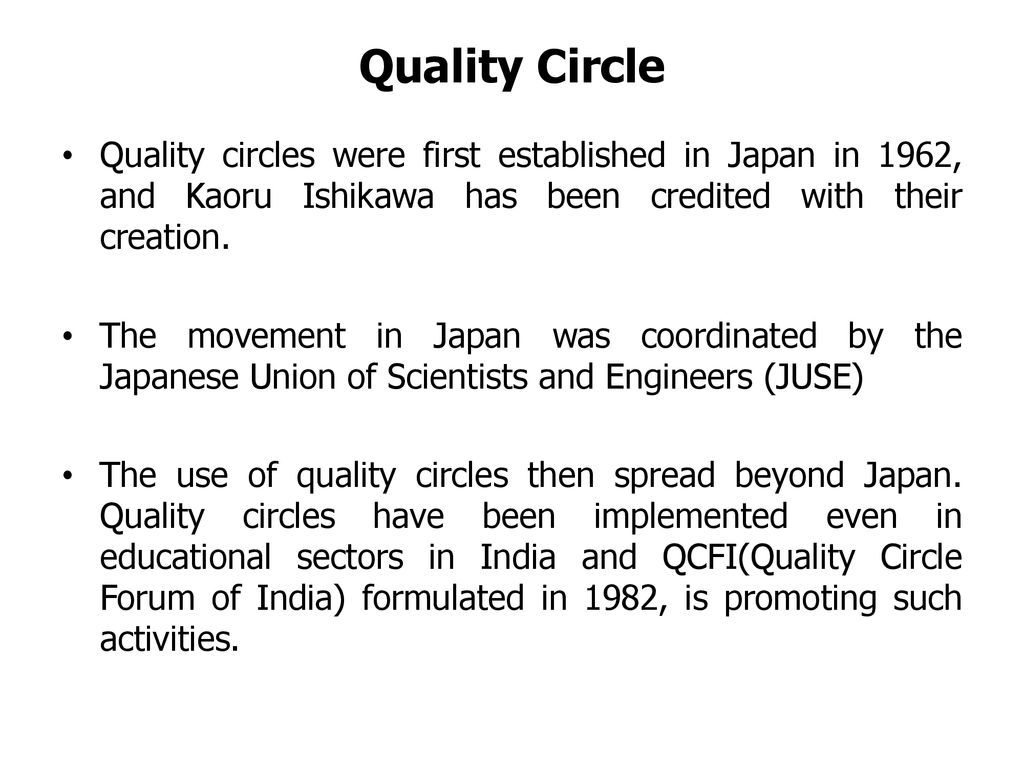

Kaoru Ishikawa was a Japanese engineer and quality control expert who is credited with developing the concept of "quality circles," also known as "Ishikawa circles." These are small groups of employees who meet regularly to discuss and identify problems within their work processes, and to propose and implement solutions to improve quality and productivity.

Ishikawa believed that the best ideas for improving quality often come from the workers themselves, as they are the ones who are most familiar with the day-to-day operations and challenges of their jobs. He argued that by empowering employees to take ownership of their work and to identify and address problems, organizations could significantly improve their operations and achieve better results.

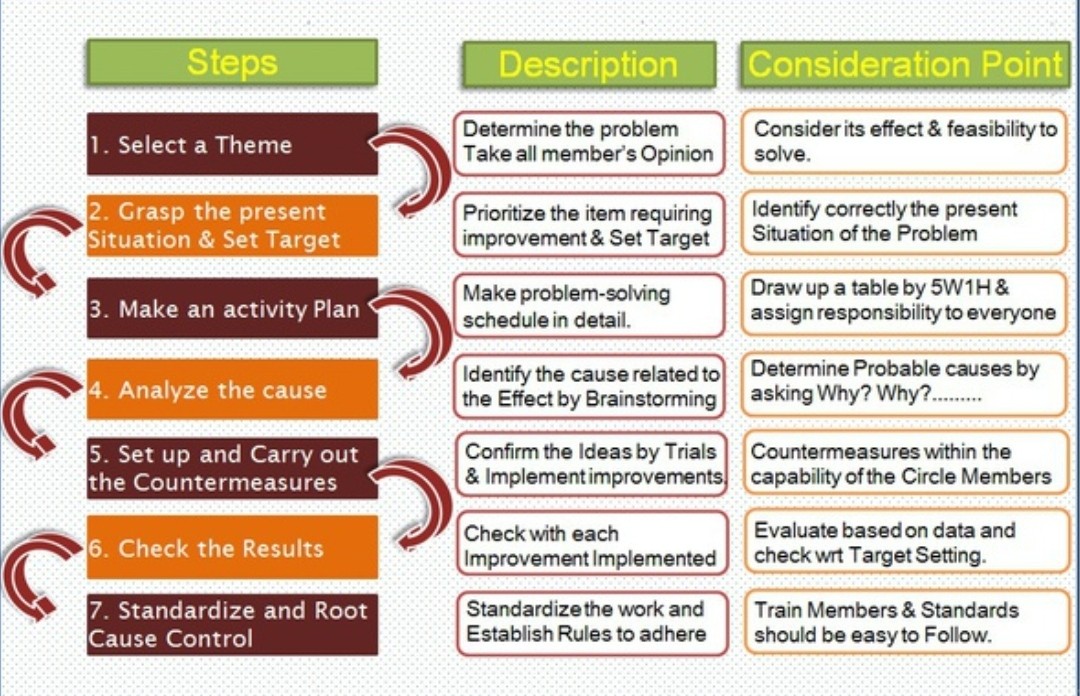

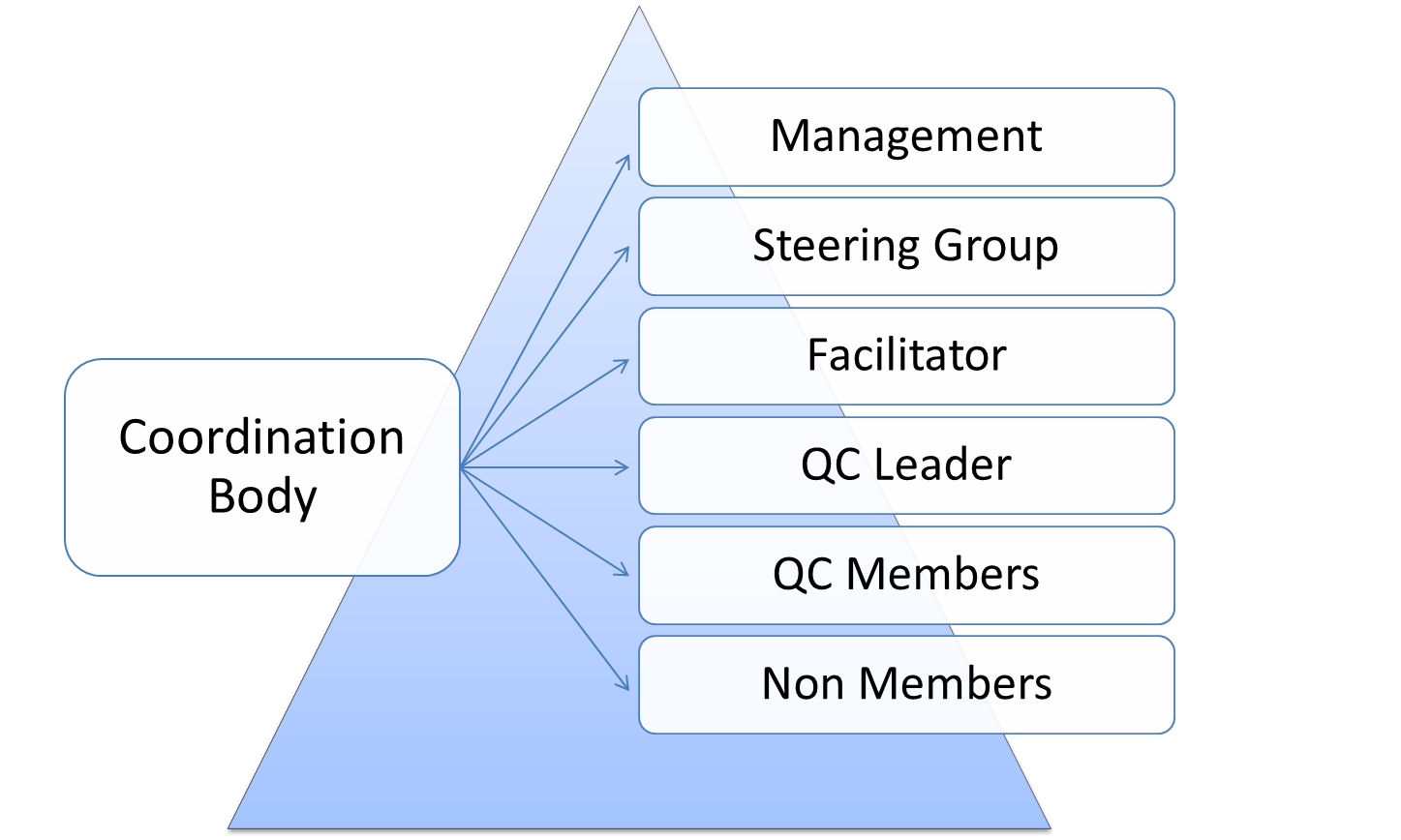

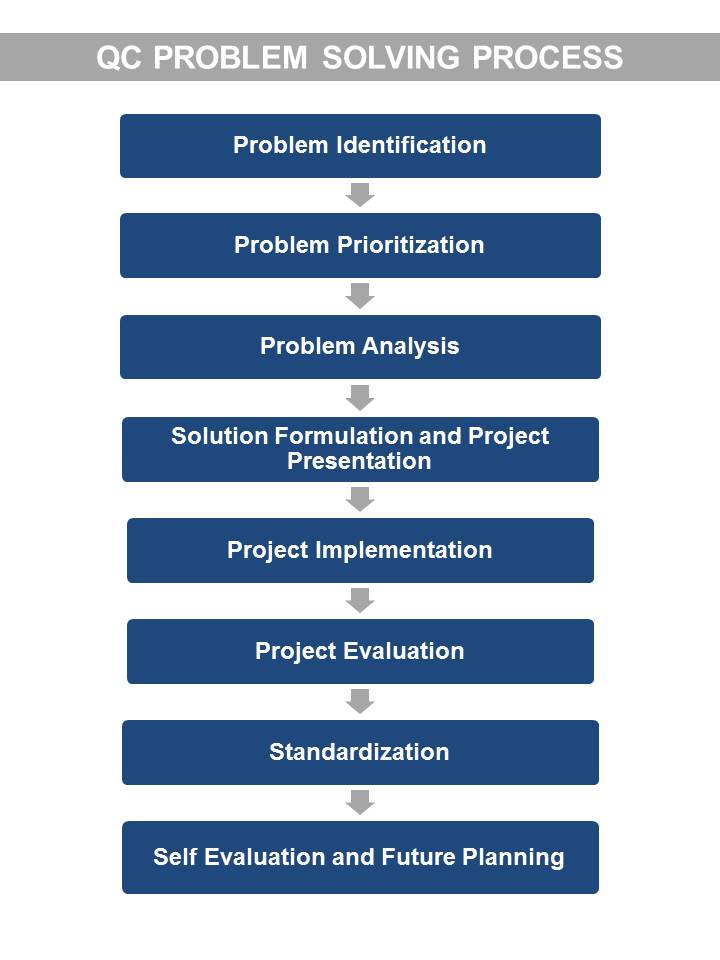

Quality circles are typically composed of a small group of employees from the same department or work area, who meet regularly (usually once a week) to discuss and analyze problems and identify potential solutions. The group is led by a facilitator, who helps to guide the discussion and ensure that all members are able to contribute.

One of the key principles of quality circles is that they are voluntary and self-managed, meaning that participation is not mandatory and the group is responsible for organizing and running its own meetings. This helps to foster a sense of ownership and commitment among group members, as they are able to take an active role in improving their work environment.

Quality circles have been shown to be effective in improving a wide range of organizational outcomes, including productivity, quality, and employee satisfaction. They can also help to build a sense of teamwork and collaboration within an organization, as employees are able to work together to identify and solve problems.

In conclusion, the concept of quality circles, developed by Kaoru Ishikawa, has proven to be a powerful tool for improving quality and productivity within organizations. By empowering employees to take ownership of their work and to identify and address problems, organizations can significantly improve their operations and achieve better results.

+is+known+as+the+father+of+quality+circles+.+Masaaki+Imai%2C+Feigenbaum(fay-ghen-bowm)%2C+Ishikawa..jpg)