Writing a thesis paper can be a daunting task, especially if you have never written one before. However, with a clear understanding of the steps involved and a little bit of planning, you can successfully write a thesis paper that is both informative and well-written. Here is a step-by-step guide on how to write a thesis paper:

Choose a topic: The first step in writing a thesis paper is to choose a topic that is both interesting and relevant to your field of study. It should be something that you are passionate about and that you have a good understanding of.

Develop a thesis statement: Once you have chosen your topic, it is time to develop a thesis statement. This is a one-sentence summary of the main point of your paper. It should be clear and concise, and it should accurately reflect the focus of your paper.

Conduct research: The next step is to conduct research on your topic. This may involve reading articles, books, and other sources of information. Make sure to take thorough notes and record the sources of your information so that you can properly cite them in your paper.

Create an outline: An outline is a roadmap for your paper that helps you organize your thoughts and ideas. Start by creating an outline that includes the main points you want to cover in your paper. Then, break these points down into smaller subpoints and arrange them in a logical order.

Write your paper: Now it is time to start writing your paper. Begin by introducing your topic and explaining the purpose of your paper. Then, present your main points, using evidence and examples to support your arguments. Be sure to include in-text citations whenever you quote or paraphrase a source.

Edit and revise: After you have finished writing your paper, it is important to spend some time editing and revising. This may involve checking for grammar and spelling mistakes, rephrasing awkward sentences, and ensuring that your paper flows logically and cohesively.

Submit your paper: Once you have finished editing and revising your paper, it is time to submit it. Be sure to follow any guidelines provided by your instructor or supervisor, and double-check that you have properly formatted your paper and included all necessary citations.

By following these steps, you can write a clear and well-written thesis paper that effectively communicates your ideas and arguments. Remember to give yourself plenty of time to research, write, and revise, and don't be afraid to seek help if you need it. With a little bit of effort and dedication, you can successfully complete your thesis paper and move on to the next stage of your academic journey.

A disc bowl centrifuge is a type of machine that uses the principle of centrifugal force to separate liquids of different densities or compositions. It is a widely used tool in the chemical and pharmaceutical industries, as well as in food processing, wastewater treatment, and other fields where the separation of liquids is important.

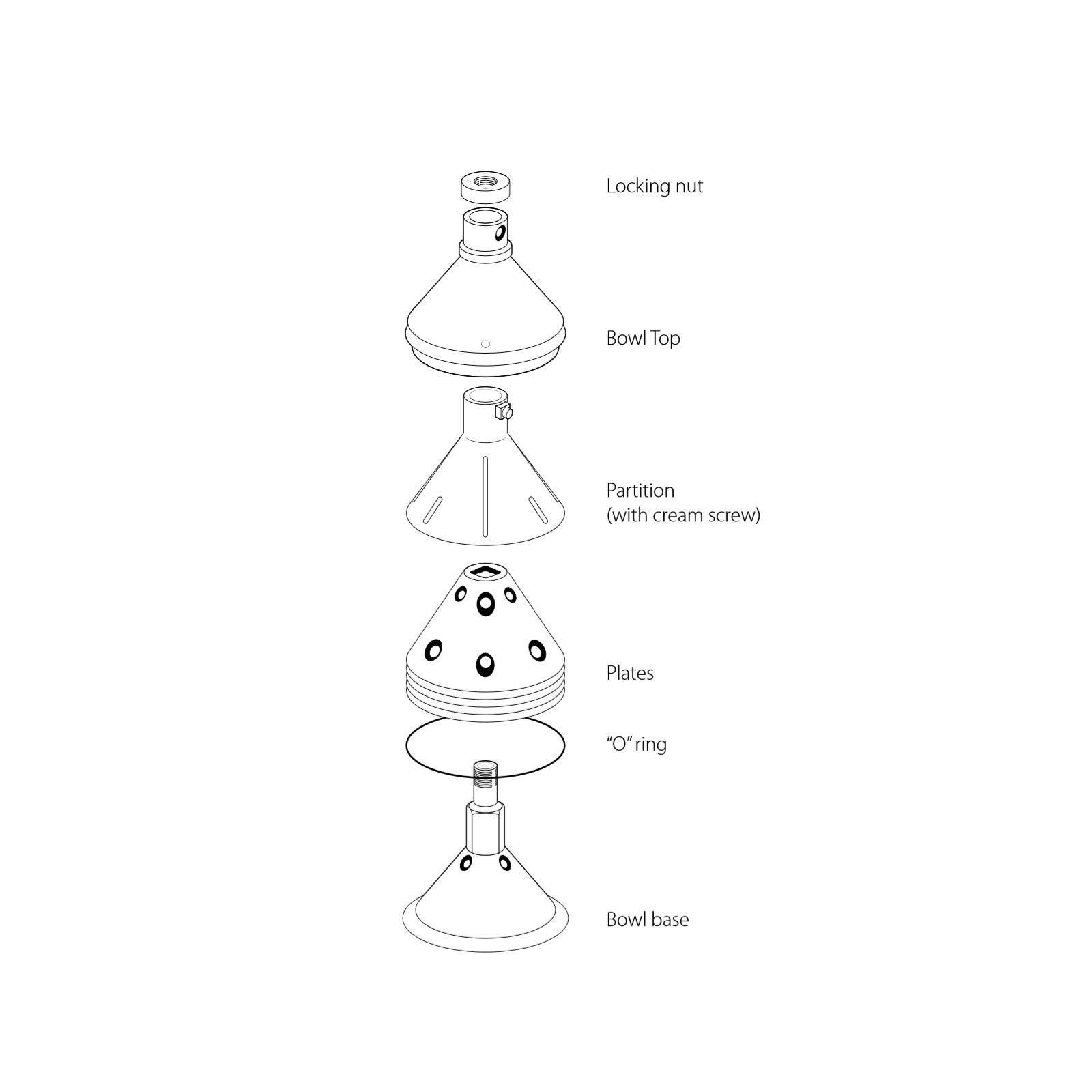

The disc bowl centrifuge consists of a cylindrical bowl that is mounted on a rotating axis. The bowl is divided into two compartments: the sedimentation compartment, where the heavier liquid settles to the bottom, and the clarification compartment, where the lighter liquid rises to the top. As the bowl rotates, the liquids are subjected to high centrifugal forces, causing them to separate according to their density.

The disc bowl centrifuge operates on the principle of differential sedimentation, which states that particles in a fluid will sediment at different rates depending on their size, shape, and density. When a liquid mixture is subjected to high centrifugal forces, the heavier particles will sediment more quickly than the lighter ones. By adjusting the speed and duration of the centrifugation process, it is possible to achieve a high degree of separation between the two liquids.

One of the key advantages of the disc bowl centrifuge is its high separation efficiency. It can achieve separations with a purity of up to 99% or higher, depending on the nature of the liquids being separated and the desired degree of separation. This makes it a useful tool for purifying and concentrating a wide range of liquids, including biological fluids such as blood, urine, and serum, as well as chemical and pharmaceutical compounds.

Another advantage of the disc bowl centrifuge is its versatility. It can be used to separate a wide range of liquid mixtures, including those containing particles or contaminants that might clog or damage other types of separation equipment. It is also relatively easy to operate and maintain, making it a popular choice for many industrial and laboratory applications.

Overall, the disc bowl centrifuge is a valuable tool for separating liquids of different densities or compositions. Its high separation efficiency, versatility, and ease of use make it an essential piece of equipment in many different industries and applications.