Mechanical couplings are devices used to transmit torque and rotary motion from one shaft to another. They are used in a wide variety of applications, including power transmission, machine tooling, and robotics. There are several different types of mechanical couplings, each with its own unique characteristics and benefits. In this essay, we will explore some of the most common mechanical coupling types and their uses.

One of the most basic and widely used mechanical couplings is the rigid coupling. As the name suggests, a rigid coupling is a solid connection between two shafts that does not allow for any relative movement between them. This type of coupling is typically used in applications where precise alignment of the shafts is required, such as in machine tools or motors. Rigid couplings are also often used in situations where there is a need for high transmission of torque, such as in gearboxes or drivetrains.

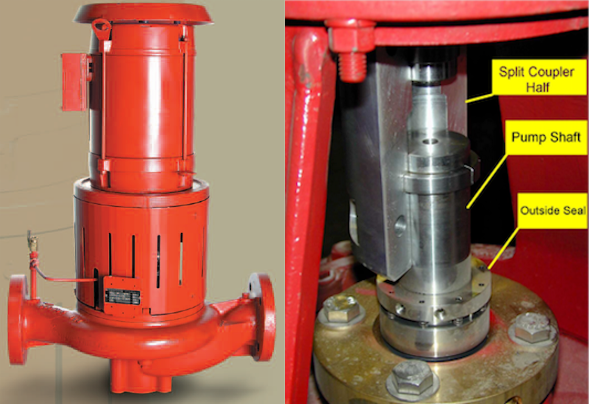

Another common mechanical coupling is the flexible coupling. As opposed to a rigid coupling, a flexible coupling allows for some degree of relative movement between the two connected shafts. This can be useful in situations where there is a need to compensate for misalignment or thermal expansion. Flexible couplings can be made from a variety of materials, including rubber, metal, and composite materials, and are often used in applications such as pumps, motors, and gearboxes.

A third type of mechanical coupling is the universal joint, or U-joint. A U-joint is a flexible coupling that allows for rotary motion to be transmitted between two shafts that are not aligned in a straight line. U-joints are typically used in drivetrains and other applications where there is a need for shafts to rotate at different angles. U-joints are often made from metal and can be found in a variety of sizes and shapes to suit different applications.

Another type of mechanical coupling is the clutch. A clutch is a type of coupling that allows for the transmission of rotary motion between two shafts to be selectively engaged or disengaged. Clutches are often used in applications where it is necessary to smoothly transfer torque from one shaft to another, such as in automobiles or machinery. There are several different types of clutches, including friction clutches, mechanical clutches, and hydraulic clutches, each with its own unique characteristics and uses.

Finally, a fifth type of mechanical coupling is the chain coupling. A chain coupling consists of a chain that is used to transmit rotary motion between two shafts. Chain couplings are often used in applications where there is a need for a flexible connection between two shafts, such as in conveyor systems or industrial machinery. Chain couplings are also often used in applications where there is a need for a high transmission of torque, such as in drivetrains.

In conclusion, mechanical couplings are an essential component in many different types of machines and systems. There are several different types of mechanical couplings, each with its own unique characteristics and benefits. Some of the most common mechanical coupling types include rigid couplings, flexible couplings, universal joints, clutches, and chain couplings. No matter the application, there is likely a mechanical coupling that is well-suited to meet the needs of the system.