Mrp mrp. What is MRP (material requirements planning)? 2023-01-04

Mrp mrp

Rating:

6,4/10

471

reviews

Gran Torino is a film directed by Clint Eastwood that was released in 2008. The film tells the story of Walt Kowalski, an elderly Korean War veteran living in a rapidly changing neighborhood in Detroit. Kowalski is a gruff and isolated man, who is struggling to come to terms with the death of his wife and the changes in his neighborhood.

One of the main themes in Gran Torino is the concept of racism and prejudice. Kowalski is a racist man who has a deep hatred for the Hmong people who have recently moved into his neighborhood. He makes derogatory comments about them and refers to them as "gooks." However, as the film progresses, Kowalski begins to form a relationship with Thao, a young Hmong boy who lives next door. Through this relationship, Kowalski begins to see the Hmong people in a different light and starts to understand the impact of his own prejudices.

Another important theme in the film is the concept of redemption. Kowalski is a bitter and angry man who has lost touch with his family and the world around him. However, through his relationship with Thao and the Hmong community, Kowalski begins to see the value in compassion and understanding. He comes to realize that he has been holding onto his anger and hatred for far too long and that it is time for him to let go.

One of the most poignant moments in the film is when Kowalski makes the decision to stand up to a group of Hmong gang members who are trying to force Thao to join their gang. Kowalski puts himself in harm's way to protect Thao and the Hmong community, showing that he has truly changed and is willing to put aside his own prejudices to do what is right.

Overall, Gran Torino is a powerful film that deals with themes of racism, prejudice, and redemption. It is a poignant reminder that it is never too late to change and that understanding and compassion can go a long way in healing the wounds of the past.

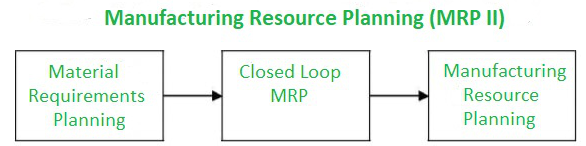

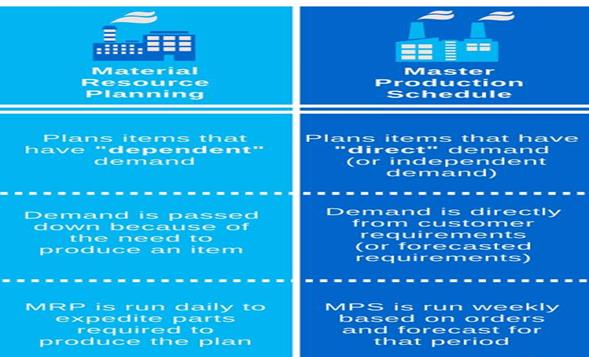

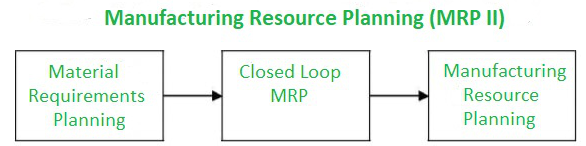

MRP vs. MRP II: What's the Difference?

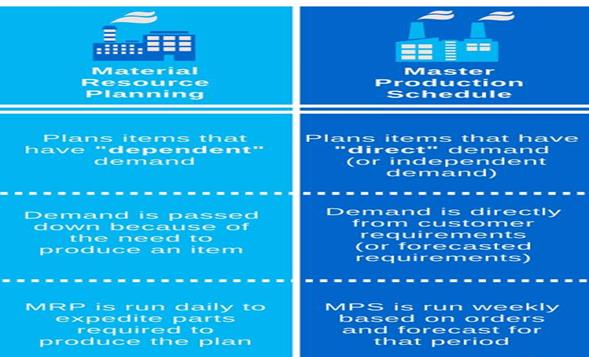

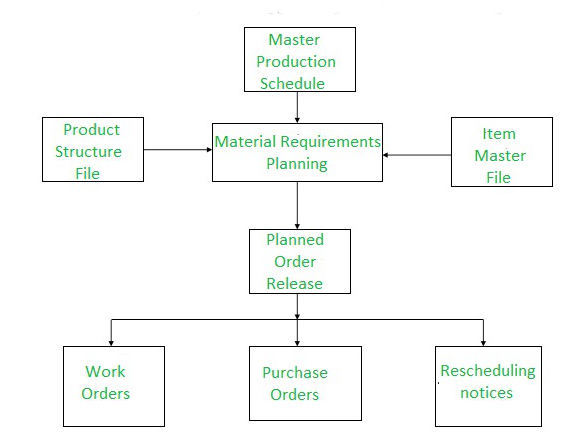

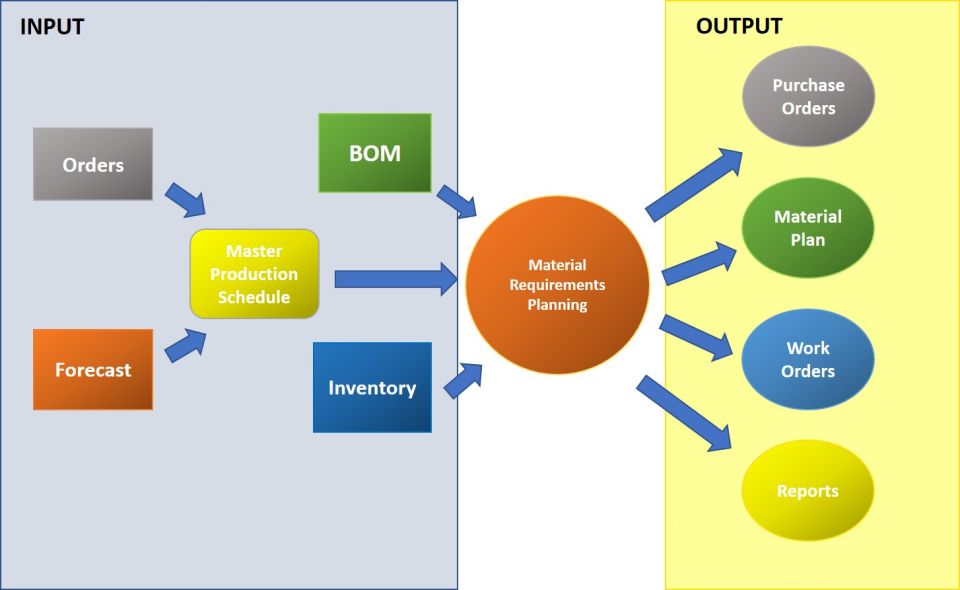

While MRP is contained within MRP II, they are not at all the same thing, and in fact, this is an easy area of confusion. Next, it checks the needed quantities against available inventory, called netting, to identify net shortages for each component. The marginal analysis looks at costs and benefits incrementally, not as an objective whole. When combined with supporting applications, such as customer orders, inventory, engineering, purchasing, production control, finance, and accounting, the suite is called manufacturing resource planning, or MRP II. On the other hand,the ERP system provides financing, manufacturing, supply chain, purchasing, selling, and planning in one single system. Do I Need ERP Software? The difference between ERP and MRP is quite straightforward.

Next

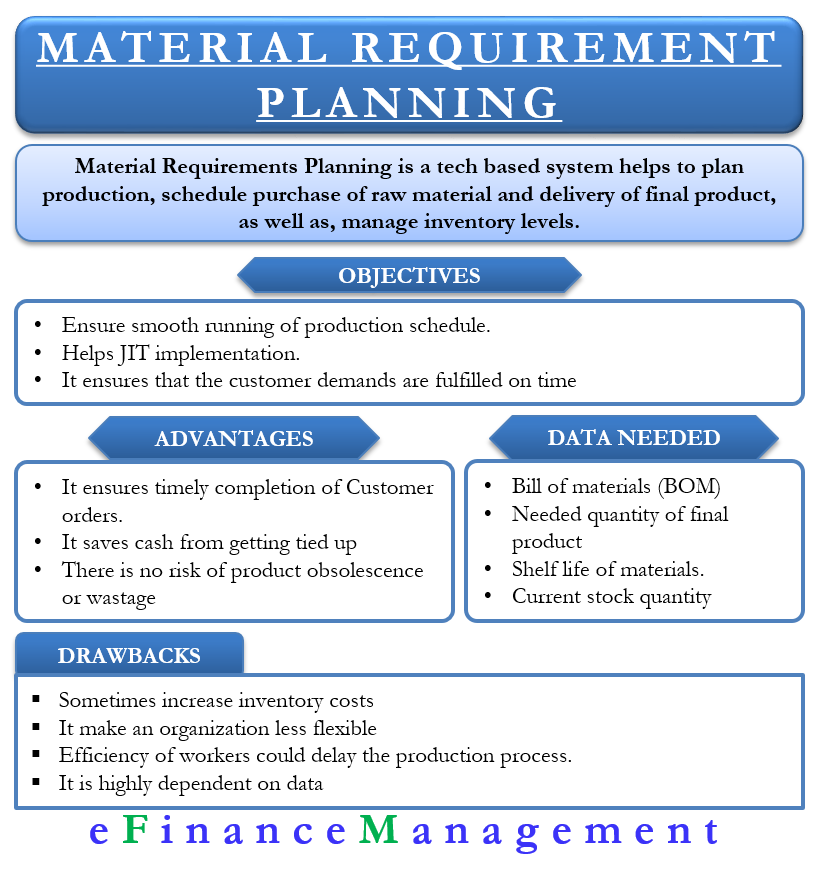

What is MRP (material requirements planning)?

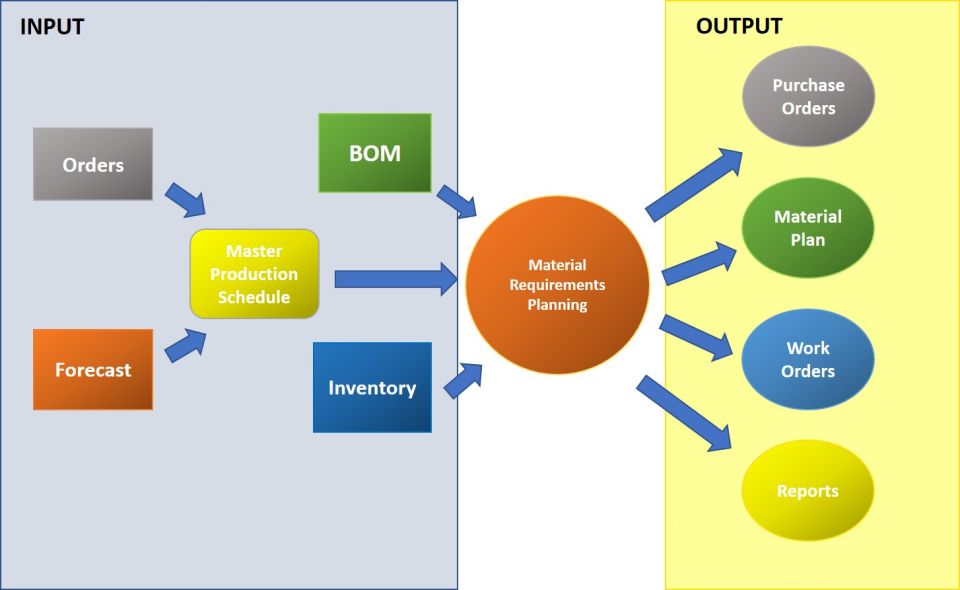

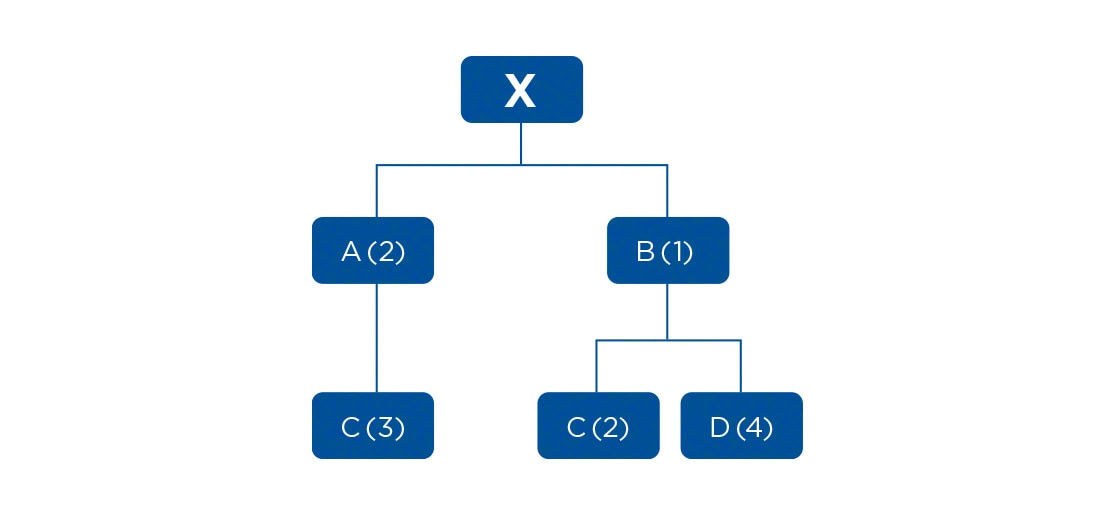

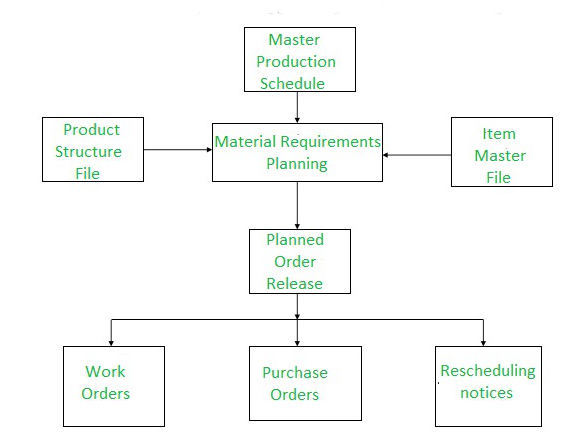

It is difficult to say exactly how effective these types of certifications were. You can select the article title to be taken to the article. Other reading of this book shows the overall process rather than the calculation orientation of MRP II. Where Did MRP II Come From? Production Scheduler module For instance, these offer more advanced scheduling and production capabilities with its system. Using the BOM and the MPS for all the products, the MRP run will, step-by-step, calculate the assemblies, components, and materials that must be produced or purchased over the planning period.

Next

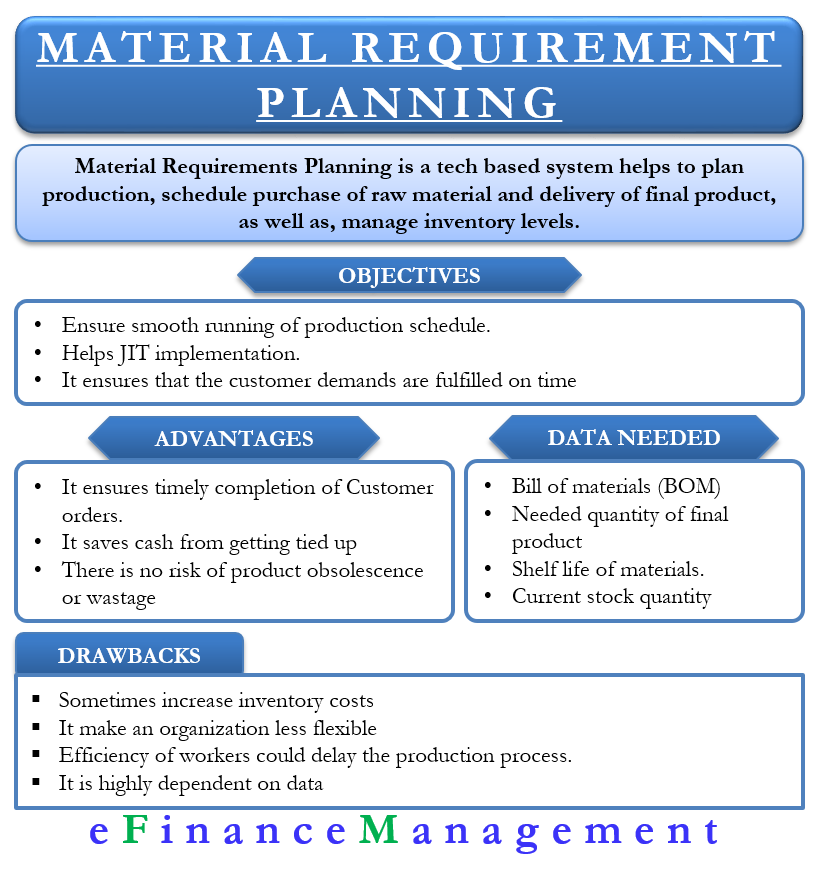

Marginal Revenue Product (MRP): Definition and How It's Predicted

But Plossl also makes the point about the sophistication of the programming being overdone —which, if you read other quotations by him, and which I cover in a separate article, is that this over-sophistication negatively impacts the implement ability of these what are now referred to as ERP applications. ERP systems often have a warehousing module as well. It is a broad-based resource co-ordination system involving other areas of a firm in the planning processes, such as marketing, finance and HR. Shelf Life: The amount of time that a product is able to remain in the warehouse is required for the planning aspect of an MRP system. Learn why so few entities in the IT space include references in their work.

Next

Material Requirements Planning (MRP)

It contains MRP within it and adds sales and distribution, finance and accounting, non MRP materials management things like stock transfer that MRP does not do. Now, companies of all sizes in many industries depend on MRP-based systems to meet customer demands for their products, control inventories, manage entire supply chains, reduce costs, and respond to market changes — including natural disasters and Definition of MRP: MRP is a system designed to plan manufacturing production. Our References for This Article If you want to see our references for this article and related Brightwork articles, visit this link. This is not a quote from 5 or 10 years ago but from 30 years ago. Send MR P Support your inquiry.

Next

The Difference Between MRP I and MRP II

That information feeds the master production schedule MPS , which is the agreement between all the stakeholders on what will be produced — such as given capacity, inventory, and profitability. Demand is the quantity and timing of customer orders and forecasts. In this, tasks which comes under manufacturing unit is automated or co-related so that the production at the end should be increased. Having too much inventory is expensive, yet having not enough can create stock-outs, which are often the main cause of production disruptions, late shipments, added costs, and poor customer service. In addition, MRP systems can be easily combined with other inventory software, but this is not the case for ERP systems. What Is Marginal Revenue Product MRP? As should be apparent, none of these criteria have anything to do with setting up MRP systems. Telephone Call an MRP Support Representative.

Next

Difference between MRP and MRP II

Aims to control relevant material flows and production capacity while also taking into account the relationship between these material flows and the required capacity. Next, it checks the needed quantities against available inventory, called netting, to identify net shortages for each component. It is Factor material inventory and emphasis on physical assets. The Difference Between ERP and MRP MRP II being the basic footprint of what would become ERP shows the difference between ERP and MRP. The MRP system is designed to progressively increase inventory efficiency in a business through control of manufacturing, scheduling, and purchasing. The approach was popularized in the West by the book The Machine That Changed the World by Womack, Jones, and Roos 1990. MRP PRODUCT SERVICE AND SUPPORT Get your questions answered about product setup, use and care, repair and maintenance issues.

Next

MRP is the industry leader in new & refurbished aesthetic lasers

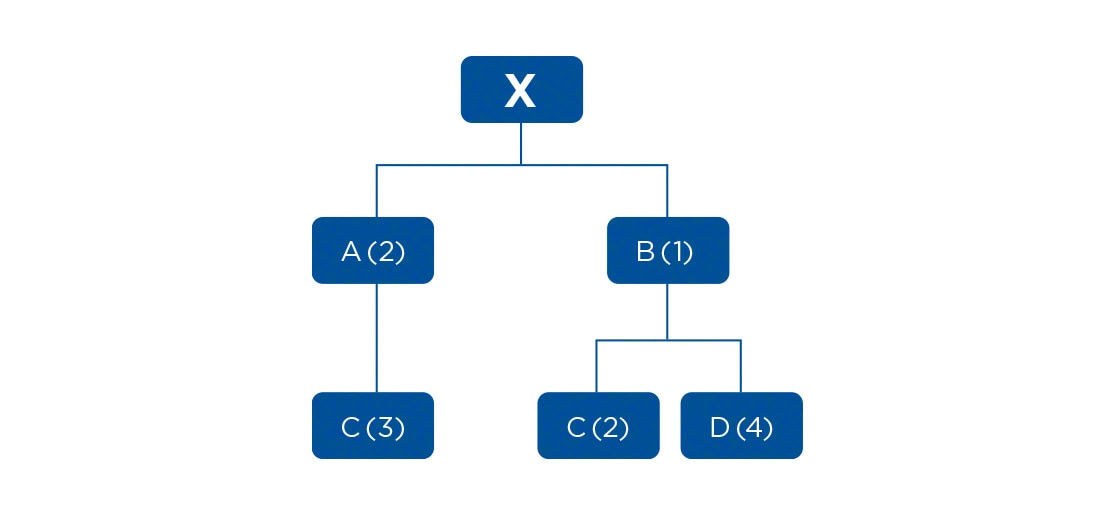

For example, the final product may have many sub-assemblies. Interestingly, 30 years after the introduction of MRP II, this problem persists. What do we do? APS, being a somewhat nebulous term, can also include supply chain planning functions and applications like demand planning and management, distribution planning, and finite scheduling, among others. Indeed, Oliver Wight has consulted at quite a few companies and had lived through the migration of companies to MRP systems. Engineering is responsible for creating and managing the bill of materials BOM for all final products and sub-assemblies. Or, the Demand Forecast may be completely useless for manufacturing purposes, forcing the person responsible for the master schedule to literally generate his own forecast in an attempt to predict what the demand actually will be.

Next

What is The Difference Between MRP and MRP II?

Make-to-stock companies emphasize forecasts while other companies use a combination of orders and forecasts for planning future production. This was proven incorrect as companies continued to use their legacy systems and ERP after ERP was implemented and then purchased more applications and connected them to the ERP system. MRP II focuses on integrating MRP and the new functionalities of capacity planning and detailed scheduling. Also called a product structure, the BOM is a hierarchical model of exactly what goes into each unit. As should be apparent, none of these criteria have anything to do with setting up MRP systems. MRP II was introduced based on the marketing platform that MRP had not achieved its objectives. MRP Chatbot 24x7 Support with Chatbot! And, therefore, to the rest of the business.

Next