Pediococcus is a type of bacteria that is commonly found in beer, particularly in styles such as lambic and sour ales. While it is not intentionally added to beer, it can sometimes be present as a result of spontaneous fermentation or through contamination during the brewing process.

Pediococcus bacteria are lactic acid producers, meaning they produce lactic acid as a byproduct of their metabolic processes. In beer, this lactic acid can contribute to the sourness and tartness of the finished product. In addition to producing lactic acid, Pediococcus bacteria can also produce diacetyl, a compound that imparts a buttery or butterscotch flavor to beer.

While the presence of Pediococcus in beer can contribute to the desired flavor profile of certain styles, it can also be a problem if it is present in large amounts or if it is not balanced with other flavors. If the levels of lactic acid produced by Pediococcus are too high, it can result in a beer that is overly sour or tart, which may not be appealing to some drinkers. Similarly, if the levels of diacetyl produced by Pediococcus are too high, it can result in a beer that has a strong, off-putting buttery flavor.

To control the presence of Pediococcus in beer, brewers may use various techniques such as carefully controlling the pH of the brewing environment, using sterile equipment and sanitizing practices, and blending different batches of beer to balance flavors. In some cases, brewers may also use specific strains of yeast or bacteria that can inhibit the growth of Pediococcus or consume the lactic acid and diacetyl that it produces.

Overall, Pediococcus is an important microorganism in the brewing of certain styles of beer, but its presence must be carefully managed in order to produce a high-quality product. By understanding the role of Pediococcus in the brewing process and implementing appropriate techniques to control its growth and impact on flavor, brewers can produce beer that is rich in complex flavors and aromas.

Lactic Acid Bacteria Detection

Colonies growing have sour odour. The beer may turn sour. Beer with a serious lactobacillus infection will often become hazy. Which Is Responsible For Bitter Flavour Of Beer? In Cheddar cheese ripened at 6°C, a generation time of 8. Beer is an incredibly popular beverage, enjoyed by people of all ages around the world. There are many species of lactobacillus, including L brevis, L lindneri, and L delbrueckii. This polysaccharide, kefiran, is produced by the predominating bacterial species, including L.

The Real Beer Spoilers of Lactobacillus & Pediococcus

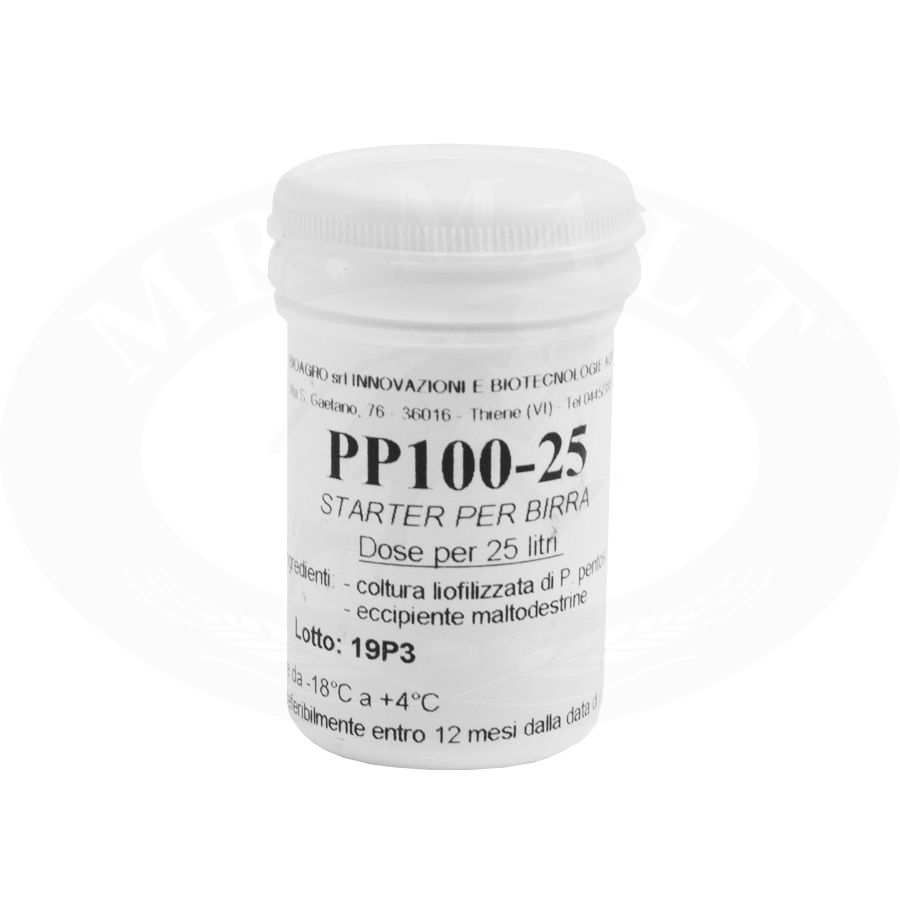

The pediococci are facultatively anaerobic to microaerophilic. Lactic acid production by P. In addition to diacetyl, other compounds, such as acetaldehyde or higher alcohols, can also contribute to buttery off-flavors in beer. The substrates used as energy sources within the ripening cheese are not well known. Bitter varieties of cassava tubers contain the cyanogenic glycoside linamarin, which can be detoxified by species of Leuconostoc, Lactobacillus, and Streptococcus in gari and fufu, a fermented cassava food of Africa, and thereby rendered safe to eat. One report claims that a pediococcal bacteriocin inhibited spores of Clostridium botulinum. Results can be monitored in real-time to detect the presence and relative abundance of contaminants.

lactobacillus

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/25/9c/259c81c3-f0a3-428a-bc8a-ba143c6a21e0/42-69332292.jpg)

Of the 16 recognized species, Pediococcus damnosus is by far the most commonly encountered beer contaminant, probably because it has evolved tolerance of hop iso-alpha acids using a variety of molecular mechanisms. Isohumulones, or hops, are chemicals that have an impact on the brewing process. It is known for its slightly bitter taste, but sometimes beer can have a strange, buttery flavor. Astiasarán, in Encyclopedia of Food and Health, 2016 Polyphenols and Flavonoids Health beneficial effects are attributed to polyphenols and flavonoids present in vegetable products. Nonstarter organisms found in the surface smear include yeasts, G.

Distribution of Lactobacillus and Pediococcus in a Brewery Environment

Sample collection and prep is simple, and can be completed by brewing staff with minimal training. Lactobacillus brevis is involved in the production of a wide variety of fermented products Table 8 , reflecting the different diets and needs in various parts of the world. It is also caused by yeast autolysis, but infection by anaerobic bacteria is more likely to cause this off-flavor. It is also critical to minimize oxygen exposure as soon as fermentation begins. Two hop resistant related genes known as horA and horC have been shown to enable lactic acid bacteria, such as Lactobacillus spp and Pediococcus spp, to grow in beer.

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/25/9c/259c81c3-f0a3-428a-bc8a-ba143c6a21e0/42-69332292.jpg)