Siemens NX is a powerful computer-aided design, manufacturing, and engineering (CAD/CAM/CAE) software suite developed by Siemens Digital Industries Software. The software is designed to help engineers and designers create and analyze complex designs and manufacturing processes for a wide range of industries, including automotive, aerospace, and consumer products. Siemens NX 7.5 is a specific version of the software that was released in 2013 and has since been superseded by newer versions. However, it is still used by many companies and individuals as a reliable and powerful tool for their design and manufacturing needs.

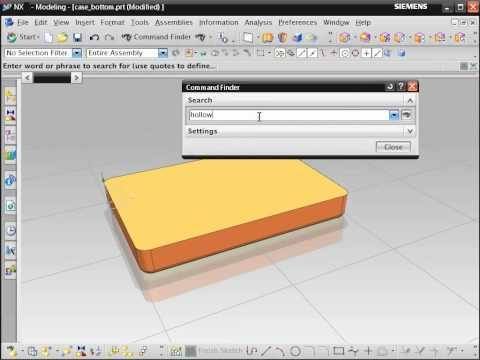

One of the key features of Siemens NX 7.5 is its advanced 3D modeling capabilities. The software allows users to create highly detailed and accurate 3D models of parts and assemblies using a variety of modeling techniques, including solid modeling, surface modeling, and mesh modeling. It also includes a range of tools for creating and modifying 3D models, such as sketching, extrusion, revolution, and sweep.

In addition to 3D modeling, Siemens NX 7.5 also includes a range of tools for analyzing and simulating the performance of designs. This includes tools for finite element analysis (FEA), which allows users to predict the behavior of a design under different loads and conditions. It also includes tools for computer-aided engineering (CAE), which allow users to analyze the performance of designs in terms of factors such as stress, strain, and deformation.

Siemens NX 7.5 also includes a range of tools for manufacturing and production. This includes tools for generating accurate and efficient toolpaths for CNC machining, as well as tools for creating detailed manufacturing drawings and instructions. The software also includes a range of tools for managing and coordinating the production process, including tools for scheduling, resource planning, and quality control.

Overall, Siemens NX 7.5 is a powerful and comprehensive software suite that is widely used by engineers and designers for a range of applications. Its advanced 3D modeling, analysis, and manufacturing tools make it a valuable tool for optimizing the design and production of complex products.