Statistical quality control (SQC) is a method used to ensure that products meet certain quality standards by using statistical techniques to monitor and control the production process. In the construction industry, this can be particularly important for ensuring the quality of concrete, which is a vital component in many structures.

Concrete is a composite material made up of water, cement, fine and coarse aggregates, and sometimes other additives. It is widely used in construction due to its strength, durability, and versatility. However, the quality of concrete can vary greatly depending on the materials used and the methods employed in its production.

To ensure the quality of concrete, SQC techniques can be used at various stages of the production process. This includes testing the raw materials, monitoring the mixing and curing process, and evaluating the finished product.

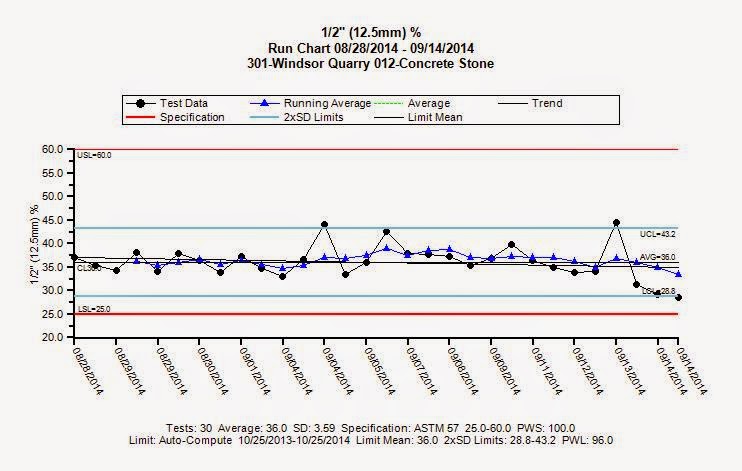

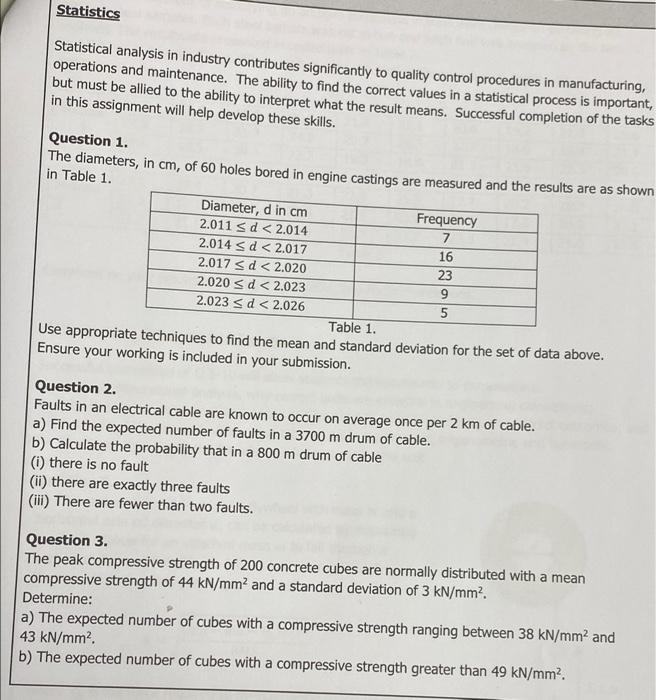

One common method of SQC in concrete production is the use of control charts. A control chart is a graph that plots the results of a series of measurements over time. By comparing the results to predetermined limits, it is possible to detect trends or deviations that may indicate a problem with the production process. For example, a control chart could be used to monitor the strength of concrete specimens as they cure, allowing for the identification of any problems with the mix or curing process.

Another important aspect of SQC in concrete production is the use of statistical process control (SPC). SPC involves analyzing the data from the control chart to identify the root cause of any deviations from the desired quality standards. This can involve analyzing the raw materials, the production process, or the finished product. By identifying and correcting the root cause of any quality issues, it is possible to improve the overall quality of the concrete.

In addition to control charts and SPC, there are many other SQC techniques that can be used in the production of concrete. These include acceptance sampling, which involves testing a random sample of the finished product to determine if it meets the required quality standards, and design of experiments (DOE), which involves systematically manipulating variables in the production process to determine their effect on the quality of the concrete.

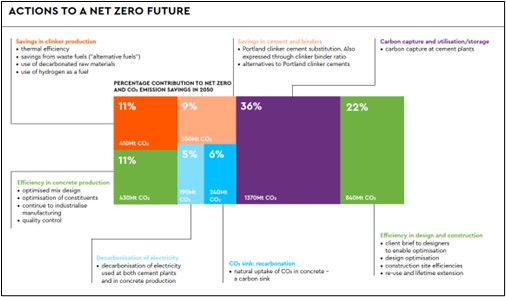

Overall, the use of SQC techniques is crucial for ensuring the quality of concrete in construction projects. By monitoring and controlling the production process, it is possible to produce concrete that meets the required quality standards and performs well in its intended application.