Summit Electric, a leading manufacturer of electrical components, has recently implemented a new enterprise resource planning (ERP) system to improve the efficiency and effectiveness of their business operations. The implementation of this new system has had a significant impact on the company, allowing them to streamline their processes, increase productivity, and make better informed business decisions.

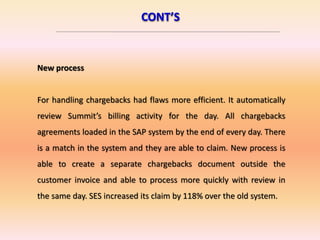

Before implementing the new ERP system, Summit Electric was using a patchwork of different software systems to manage various aspects of their business, such as inventory management, financial reporting, and customer relationship management. This made it difficult for the company to get a comprehensive view of their operations, leading to inefficiencies and missed opportunities.

The new ERP system, on the other hand, integrates all of these different systems into a single platform, providing a comprehensive overview of the business and enabling real-time data analysis. This has allowed Summit Electric to identify bottlenecks in their processes and make adjustments to improve efficiency. For example, the company has been able to reduce lead times by 30% by implementing just-in-time inventory management techniques made possible by the new ERP system.

In addition to improving efficiency, the new ERP system has also allowed Summit Electric to make better informed business decisions. With real-time data analysis, the company is able to identify trends and patterns in their operations that were previously hidden, allowing them to make data-driven decisions about where to allocate resources and make investments.

Overall, the implementation of the new ERP system has been a major success for Summit Electric. By streamlining their processes, increasing productivity, and enabling better informed business decisions, the company has been able to achieve significant improvements in their operations. As a result, Summit Electric is well-positioned to continue growing and expanding in the future.